- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

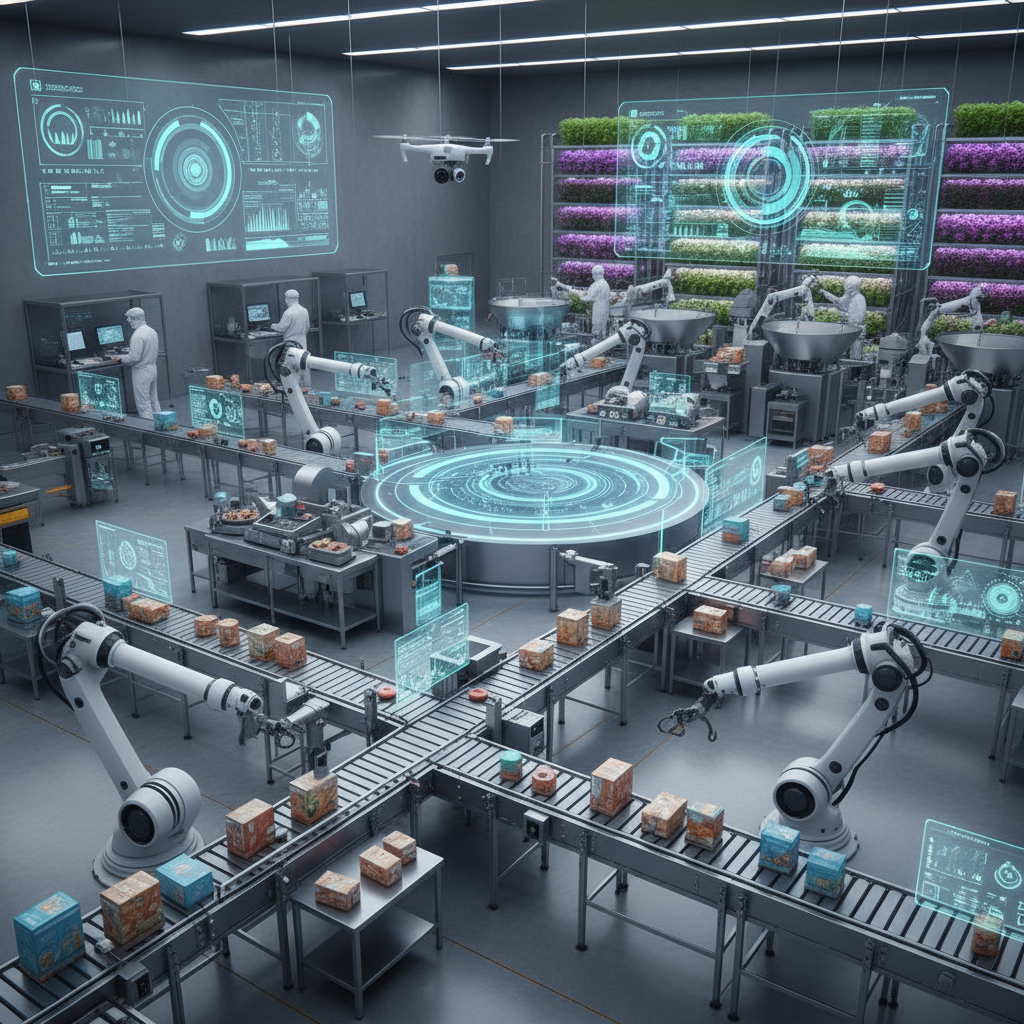

In recent years, the food processing industry has witnessed a rapid transformation driven by innovative technologies and digital advancements. As we look ahead to 2025, the integration of these top digital trends is set to redefine how food is produced, packaged, and delivered, enhancing efficiency and sustainability throughout the entire supply chain. The adoption of smart technologies such as artificial intelligence, automation, and big data analytics is not only streamlining processes but also elevating the quality and safety of food products.

As consumer demands evolve, the food processing sector must adapt to meet new expectations regarding transparency, health, and environmental impact. Digitalization will play a crucial role in this transformation, enabling manufacturers to gain insights into consumer behavior, optimize production lines, and reduce waste. The next few years will be pivotal, as the top 10 digital trends emerge to reshape how food processing companies operate, providing them with unprecedented opportunities for innovation and growth.

This article will delve into the top digital trends poised to transform the food processing industry by 2025, highlighting how these developments can lead to a more resilient and responsive sector that is better equipped to tackle the challenges of the future.

The food processing industry is experiencing a seismic shift due to emerging technologies that significantly enhance food safety and quality control. Innovations such as IoT sensors, blockchain technology, and AI-driven analytics are paving the way for more transparent and efficient operations. IoT sensors, for instance, allow real-time monitoring of food conditions during production and transportation, ensuring that products remain within safe temperature ranges and other critical parameters.

**Tips:** When implementing IoT solutions, consider starting with a pilot program to assess effectiveness before a full-scale rollout. This approach can help identify potential issues and gather insights without overwhelming your resources.

Moreover, blockchain technology plays a crucial role in traceability, enabling manufacturers to track the entire journey of a food product from farm to table. This level of transparency not only enhances consumer trust but also aids in swift recall processes when necessary. AI-driven analytics further allow companies to predict potential quality control issues by analyzing patterns in data.

**Tips:** Invest in training your team on new technologies to ensure everyone is on board with the changes. A well-informed staff can better utilize these tools, leading to improved safety and quality practices throughout the production cycle.

| Trend | Description | Impact on Food Safety | Impact on Quality Control | Key Technologies |

|---|---|---|---|---|

| Blockchain Technology | Enhances traceability and transparency in the supply chain. | Improves tracking of food sources, preventing contamination. | Ensures quality verification through immutable records. | Distributed ledgers, smart contracts. |

| AI and Machine Learning | Optimizes production and predicts equipment failures. | Enhances monitoring of food conditions in real-time. | Improves consistency and reduces defects in products. | Predictive analytics, anomaly detection. |

| IoT (Internet of Things) | Connects devices for real-time data collection and monitoring. | Provides insights on conditions affecting food safety. | Enables better quality assurance through continuous monitoring. | Sensors, connected appliances, cloud computing. |

| Robotics and Automation | Streamlines production lines and reduces human error. | Minimizes risks of contamination during handling. | Enhances precision and uniformity in product quality. | Automated systems, robotic arms, process automation. |

| Big Data Analytics | Analyzes large datasets for informed decision-making. | Detects patterns that could indicate safety concerns. | Improves quality metrics and operational efficiency. | Data warehousing, real-time analysis tools. |

The food processing industry is undergoing a significant transformation driven by digital solutions aimed at enhancing sustainability.

One of the most pressing issues today is food waste, which accounts for a substantial percentage of global food production.

Innovative digital technologies, such as IoT sensors and AI analytics, are now being utilized to monitor and optimize inventory levels in real time, ensuring that products are used before they expire.

This proactive approach not only minimizes waste but also maximizes efficiency in supply chain management.

Moreover, digital platforms enable more transparent tracking of food products from farm to table.

By leveraging blockchain technology, companies can provide consumers with information about the journey of their food, fostering a deeper connection to sustainable practices.

This transparency encourages businesses to adhere to stricter regulations on waste reduction and resource management. As the industry embraces these digital trends, the synergy between technology and sustainability will play a crucial role in creating a more responsible food ecosystem, significantly reducing the environmental impact of food processing.

The food processing industry is experiencing a significant transformation, primarily driven by the integration of Artificial Intelligence (AI) into production processes. According to a report from MarketsandMarkets, the global AI in food processing market is expected to grow from $1.1 billion in 2020 to $2.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 18.1%. AI technologies are enhancing production efficiency by enabling real-time data analysis, predictive maintenance, and quality control processes. By deploying machine learning algorithms, companies can optimize supply chain management, reducing waste and improving inventory turnover rates.

Moreover, AI-driven robotics are revolutionizing labor-intensive tasks within the food processing sector. According to a study by the International Federation of Robotics, the adoption of AI and automation solutions in food processing can increase production rates by up to 30%. This advancement not only alleviates labor shortages but also ensures consistent product quality and adheres to safety regulations. As processors embrace these innovations, the role of AI in refining production workflows and enhancing operational efficiency will undeniably reshape the industry's landscape.

This chart illustrates the projected impact of various digital trends on production efficiency in the food processing industry by 2025. The trends include the application of Artificial Intelligence (AI), IoT integration, automation, big data analytics, and blockchain technology.

The smart packaging market is experiencing significant growth, driven by an increasing demand for consumer engagement and enhanced product freshness. In 2024, the AI packaging market is valued at $2.4 billion, and it is projected to grow at a compound annual growth rate (CAGR) exceeding 10.1% from 2025 to 2034. This surge is propelled by the rising needs for supply chain transparency and packaging traceability, essential for both manufacturers and consumers in ensuring product quality.

Moreover, the global vacuum packaging market is set to expand from $34.63 billion in 2024 to an impressive $53.21 billion by 2035, reflecting an average annual growth rate of 3.98%. Similarly, the dairy packaging sector is also on an upward trajectory, with a market value predicted to soar from $36.05 billion in 2025 to $64.46 billion by 2034, showcasing a CAGR of 6.67%. These statistics highlight the industry's shift towards more innovative and sustainable packaging solutions, demonstrating a commitment to meeting consumer preferences for freshness and sustainability across various applications.

Blockchain technology is revolutionizing food traceability, offering a robust solution to ensure transparency and accountability within the supply chain. By creating a decentralized and immutable ledger, blockchain enables all stakeholders—from farmers to consumers—to access real-time data about the journey of food products. Each transaction or change in ownership is recorded on the blockchain, providing an auditable trail that enhances trust and reduces the potential for fraud. This means that consumers can verify the origins of their food, ensuring it is safe, sustainably sourced, and authentic.

The implementation of blockchain in the food processing industry not only enhances traceability but also streamlines operations. With automated systems powered by smart contracts, businesses can efficiently manage recall processes, monitor compliance with safety regulations, and reduce food waste. By harnessing this technology, companies can respond quickly to any issues that may arise, such as contamination or mislabeling, thus safeguarding public health. As the industry continues to adopt blockchain solutions, the potential for improved safety, transparency, and efficiency in the food supply chain becomes increasingly apparent.