- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

Beef processing equipment plays a vital role in the food industry. According to a report by IBISWorld, the beef processing industry in the U.S. generates over $73 billion annually. This significant revenue highlights the importance of efficient equipment in meeting global meat demand. Effective equipment streamlines operations, ensuring quality and safety.

Investments in beef processing equipment are essential for businesses aiming to remain competitive. The use of advanced technology can reduce waste and improve product consistency. Reports show that proper processing can enhance food safety, reducing contamination risks. However, many facilities struggle with outdated systems, leading to inefficiencies that need to be addressed.

The need for innovative beef processing equipment is clear. Challenges remain in balancing cost and technology. Companies are encouraged to invest wisely in their processing capabilities. Embracing modern equipment can lead to better products and increased consumer trust. The stakes are high, and reflection on current practices is necessary for future success.

Beef processing equipment refers to machines and tools used in beef production. This includes grinders, slicers, and mixers designed to handle various cuts of meat. The equipment ensures meat safety and quality. Without it, the beef industry would struggle to meet consumer demands.

In beef processing, hygiene is crucial. Properly sanitized machines prevent contamination. Regular maintenance is a must to keep equipment in good shape. If machines break down, production slows, leading to losses. Many processors overlook this point, risking quality and safety.

When investing in equipment, consider the long-term benefits. Choosing durable machines can enhance processing speed. This makes meeting market demand easier. It's important to weigh costs against potential revenue. Finding the right balance can lead to more successful operations. Functionality should always come first, not just price.

Stay updated with industry trends. Technology is evolving, and so should your equipment. Upgrading machines can improve efficiency and safety standards. Don't hesitate to invest in new technologies. After all, the quality of beef processing affects everyone.

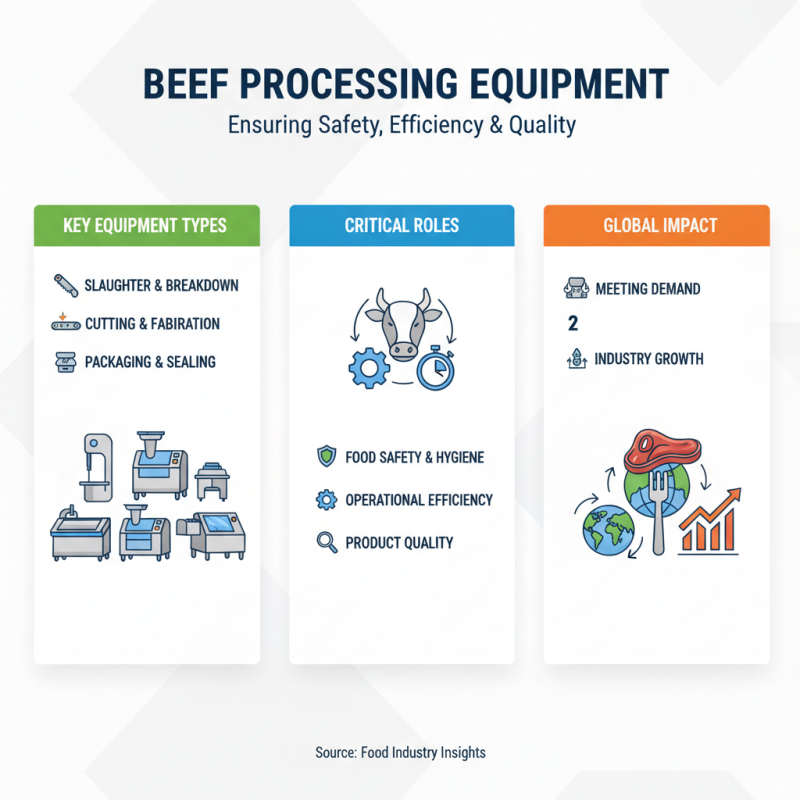

Beef processing equipment plays a critical role in the food industry. There are various types of equipment used in this sector. These tools ensure safety, efficiency, and quality in beef production. They help meet the growing demand for beef globally.

One essential category is meat grinders. These machines break down large cuts of meat into smaller, manageable pieces. According to industry data, the global meat grinder market is projected to grow by over 3% annually. This increase reflects the rising consumer demand for ground beef products. Additionally, meat slicers are vital for precision cutting. They ensure uniform thickness, which enhances presentation and cooking consistency.

Vacuum packaging equipment is another important type. It extends the shelf life of beef products. This equipment removes air, which can cause spoilage. Research shows that vacuum-sealed beef lasts significantly longer than conventionally packaged meat. However, the packaging process isn't flawless. Issues can arise, such as seal failures. These flaws can lead to contamination and loss of quality. Thus, constant evaluation of equipment efficiency is necessary.

Beef processing equipment plays a pivotal role in the food industry. It includes machines for cutting, grinding, and packaging meat. Efficient machinery enhances productivity and ensures safety. In the U.S., over 26 billion pounds of beef are processed annually, highlighting the need for advanced technology.

Key features of beef processing equipment include automation and hygiene. Automated lines improve speed and reduce human error. Machines must meet strict sanitation standards to prevent contamination. The International Meat Report indicates that automation can boost production efficiency by up to 30%. However, many plants still rely on outdated technology.

Evaluating equipment for upgrades is crucial to staying competitive. Tips: Regular maintenance can prevent costly breakdowns. Invest in training staff on new technology. Monitor production rates to identify bottlenecks. If machinery feels outdated, it may be time for a change. Embracing modern technology can make a significant difference in overall efficiency.

Beef processing equipment plays a crucial role in maintaining food safety standards. According to a report by the USDA, nearly 20% of foodborne illnesses in the U.S. trace back to beef products. Effective processing equipment helps mitigate this risk. Proper sanitation and control in processing lines are essential. Heat treatment, grinding, and packaging can all introduce contaminants if not managed well.

For example, during grinding, cross-contamination can occur if surfaces are not cleaned properly. A study from the CDC found that improper handling of raw beef led to significant outbreaks. This highlights the need for specialized equipment that facilitates safe processing. Equipment with built-in cleaning features can reduce risks significantly. However, many facilities still rely on outdated methods, creating potential hazards.

In addition, consistent monitoring is vital. Equipment should be regularly inspected and calibrated. A lack of maintenance can result in safety lapses. The importance of high-quality beef processing equipment is evident. It ensures the safety of not only the product but also the consumers. Investing in advanced technology can reduce foodborne illnesses significantly. But many in the industry are slow to adapt, reflecting a need for ongoing education and training.

Beef processing equipment plays a crucial role in the food industry, especially in ensuring quality and efficiency. The right tools can significantly impact how meat is processed. For example, cutting machines help achieve uniform sizes, leading to better cooking results. When meat is cut consistently, consumers notice an improvement in tenderness and flavor. However, not all equipment achieves this. Some machines may struggle with tough cuts, leaving inconsistency in the final product.

Efficiency is another area where beef processing equipment shines. Modern machinery can handle large volumes of meat quickly. Automated systems reduce labor costs and minimize human error. However, relying too much on automation can be risky. Machines require regular maintenance; neglecting this can lead to breakdowns. Equipment that frequently malfunctions can slow down production and affect quality.

Moreover, the upfront investment in quality equipment can be daunting. Smaller processors may find it hard to justify these costs. The challenge lies in balancing investment and returns. While low-quality machines may save money short term, they can lead to long-term losses. In the end, choosing the right beef processing equipment is about finding a balance between quality, efficiency, and cost.

| Dimension | Description | Importance |

|---|---|---|

| Cutting Equipment | Tools used for slicing, dicing, and portioning beef cuts. | Ensures uniform sizes for cooking and packaging, improving presentation. |

| Grinding Machines | Equipment designed to grind beef into different textures. | Facilitates production of ground beef products with consistent quality. |

| Vacuum Sealers | Machines that remove air and seal beef products in packaging. | Extends shelf life and maintains quality by preventing freezer burn. |

| Temperature Control Systems | Equipment that monitors and regulates temperature during processing. | Ensures food safety and quality by preventing spoilage. |

| Hygiene Stations | Facilities for cleaning equipment and worker hygiene before processing. | Essential for preventing contamination and ensuring product safety. |

| Labeling Machines | Devices that automate the labeling process for retail packages. | Improves efficiency in the supply chain and provides product information. |