- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

When selecting the right poultry processing equipment, many factors come into play. The industry is evolving rapidly, and 2026 promises new innovations. Choices are plentiful, but not all equipment is created equal.

Consider the needs of your operation. Are you a small family farm or a large commercial processor? The scale of production heavily influences equipment choice. Some machines focus on speed, while others emphasize precision and hygiene. It's crucial to match your equipment to your goals.

There's also the aspect of affordability. High-quality poultry processing equipment may come with a higher price tag, yet it can lead to savings in the long run. Reflect on what aspects you can compromise. Making decisions in this area requires careful thought, ensuring both effective processing and compliance with regulations.

Poultry processing equipment plays a crucial role in modern agriculture. It ensures efficiency and hygiene in meat production. Properly designed machines help reduce waste and improve yield. Each step of processing needs specific equipment that maintains quality. Key areas include slaughtering, defeathering, evisceration, and packaging. These tasks require reliable machinery that can handle volume and speed.

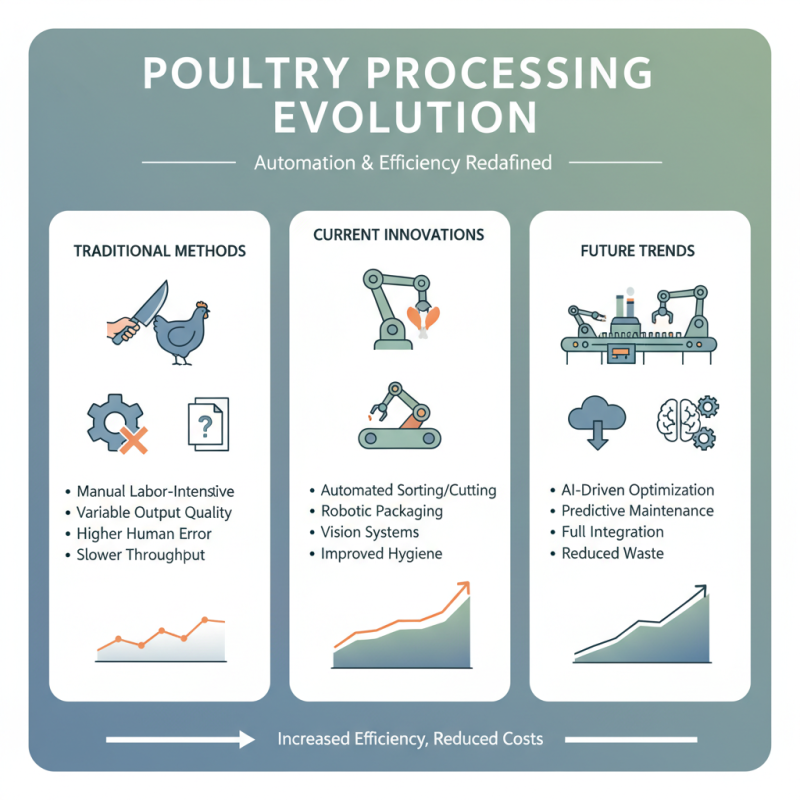

Technology trends in poultry processing are striking. Automation and robotics are on the rise. They enhance precision and limit human contact. In addition, advancements in data analytics help optimize operations. Monitoring systems track equipment performance and maintenance needs. However, not every processor adopts these technologies. Some may feel overwhelmed or lack resources. It’s a challenge that requires thoughtful planning and investment.

Moreover, sustainability is becoming a focus. Eco-friendly equipment options emerge, aiming to reduce carbon footprints. Water and energy efficiency are key considerations. While innovations are exciting, they can also present difficulties. Finding a balance between cost and sustainability is essential for processors. As technology evolves, so will the strategies to implement these solutions effectively.

| Equipment Type | Key Features | Production Capacity (units/hour) | Technology Trends |

|---|---|---|---|

| Feathers Removal Machine | High efficiency, adjustable speed | 2000 | Automation, AI Integration |

| Evisceration Equipment | Hygienic design, easy to clean | 1500 | Robotics, Smart Sensors |

| Chilling Units | Energy efficient, continuous flow | 3000 | IoT Monitoring, Predictive Maintenance |

| Packaging Machines | Flexible, high-speed operation | 2500 | Automation, Eco-friendly Materials |

| Quality Control Systems | Real-time monitoring, defect detection | 1000 | AI Analysis, Data Integration |

When selecting poultry processing equipment, several key factors come into play. Efficiency is critical. Industry reports indicate that automating the deboning process can improve productivity by up to 30%. This means more output with less labor, which is vital in today's competitive market. However, not all automation is flawless. Some machines may jam or require frequent maintenance, leading to downtime.

Cost-effectiveness is another major factor. Investing in high-quality equipment can seem expensive initially, but it often pays off in the long run. According to recent surveys, companies that chose durable equipment saw a 20% reduction in operating costs over five years. Yet, it’s essential to remember that cheaper options may lead to higher repair costs. It's a gamble that should be analyzed carefully.

Safety and hygiene standards must not be overlooked. Equipment should meet industry regulations to prevent contamination. Despite advancements, some machines still struggle with cleaning. Regular inspection is necessary to ensure compliance. Additionally, employee training is crucial for safe operation. Equipment that’s not user-friendly can lead to accidents or inefficiencies. Balancing these aspects requires thoughtful consideration.

Choosing the right poultry processing equipment is essential for efficiency. Many brands offer various machines tailored to different needs. Each piece of equipment has its strengths and weaknesses.

Some brands focus on speed, providing machines that process large quantities in a short time. Others prioritize quality, ensuring that the final product meets high standards. It's crucial to weigh these factors carefully. Equipment that excels in one area may fall short in another.

Additionally, ease of maintenance is often overlooked. A complex machine may require frequent repairs. This could lead to increased downtime. Sometimes, simpler designs work better. Investing in reliable machinery can save time and money in the long run. Buyers should always research and compare options to find the best fit for their specific operations.

Poultry processing equipment is evolving rapidly. Many innovations are reshaping how we handle and prepare poultry. The focus is shifting towards automation and efficiency. Advanced machines can sort, cut, and package with minimal human input. This reduces labor costs while increasing output.

One notable feature is the integration of smart technology. For example, some machines now offer real-time monitoring. They provide data on production rates and equipment health. This allows for timely maintenance, minimizing downtime. However, relying too much on technology can lead to oversight. It’s essential to balance automation with skilled labor.

Another emerging trend is sustainability. Equipment designed for minimal waste is gaining attention. Machines that recycle water and reduce energy consumption are becoming standards. Yet, transitioning to these machines requires substantial investment. Many operators find this process daunting. Careful planning and budgeting are essential to make the switch effective.

Efficient poultry processing operations hinge on proper maintenance and safety practices. A recent report indicates that equipment failure can lead to significant downtime, costing facilities hundreds of thousands annually. Regular inspections and maintenance schedules are crucial. Facilities should strive for a goal of less than 2% equipment downtime. Creating checklists for maintenance can help keep operations flowing smoothly.

Safety is just as vital. In 2023, the poultry industry experienced a 20% increase in workplace accidents linked to poor equipment handling. Proper training programs for employees should be developed and regularly updated. Emphasizing personal protective equipment (PPE) usage can reduce injury risks substantially. For instance, ensuring that all workers are wearing the correct footwear can minimize slip hazards in wet areas.

Moreover, a culture of safety must be promoted. Leaders should actively engage with teams to gather feedback on safety practices. This transparency can reveal areas needing improvement. Facilities often overlook minor issues, leading to larger problems later. Regular safety drills can enhance awareness and preparedness. Maintaining a tidy workspace is also crucial, as clutter often leads to accidents. Streamlining these processes can significantly elevate both efficiency and safety standards in poultry processing operations.