- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

Choosing the right food processing machinery is a pivotal decision for any food business, as it directly impacts production efficiency, product quality, and overall operational costs. With the myriad of options available on the market, navigating through the choices can be overwhelming. Therefore, understanding the specific requirements of your business and the capabilities of different machinery is essential. Whether you're a small artisan producer or a large-scale manufacturer, the ideal food processing machinery should align with your production goals and facilitate a smooth workflow.

When selecting food processing machinery, factors such as the type of food products, processing volumes, and desired end results must be considered. Additionally, the technological advancements in food processing have led to innovations that enhance automation, reduce waste, and improve food safety. Making an informed choice requires careful evaluation of not only the machinery's performance and reliability but also its adaptability to future needs. Ultimately, investing in the right food processing machinery sets the foundation for operational success and long-term growth in the competitive food industry.

When selecting food processing machinery, it is crucial to first identify your business's specific needs. This involves assessing the type of products you will be handling, the scale of your production, and the desired outcomes for your processing operations. For instance, if your business focuses on high-volume production, machinery that operates at greater speeds and efficiency will be necessary. Conversely, a business dealing with specialty, small-batch items may prioritize flexibility and versatility in their equipment choices.

Additionally, it is important to consider factors such as the layout of your processing facility, workforce capabilities, and maintenance requirements. Understanding the physical space available will help determine the size and type of machinery that can be accommodated without hindering workflow. Furthermore, evaluating the skill level of the operators can influence the complexity of the technology you choose; user-friendly machinery may be more suitable for a less experienced team. By taking the time to address these specific requirements, businesses can make informed decisions that not only enhance productivity but also ensure the quality and safety of their food products.

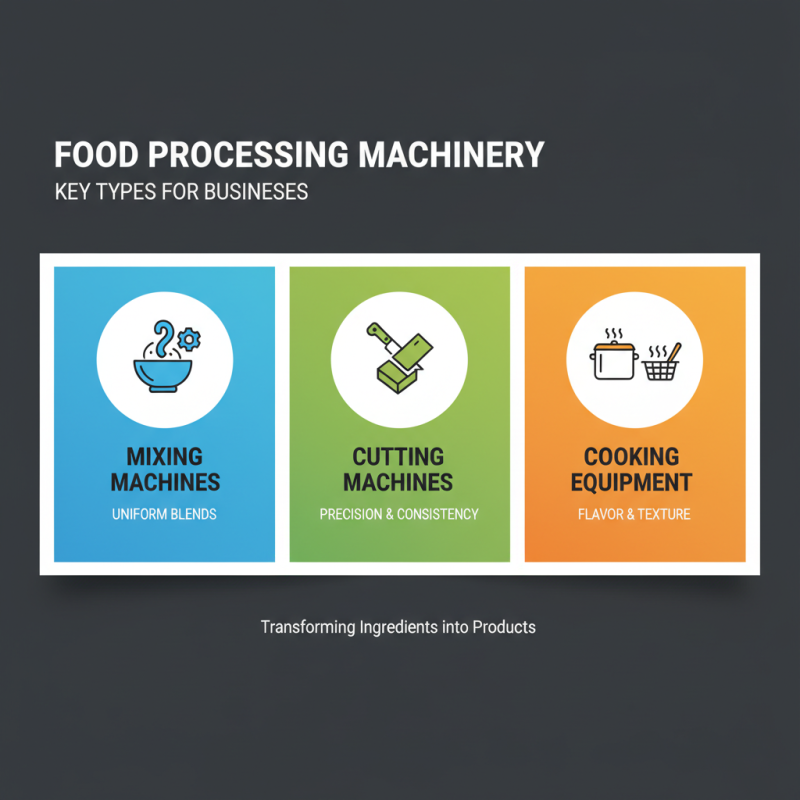

When selecting food processing machinery for your business, it's essential to understand the different types of equipment available. Each type of machinery serves a unique purpose and is tailored to specific processing needs. For instance, mixing machines are crucial for creating uniform blends of ingredients, while cutting machines are employed to ensure precision and consistency in product sizes. Additionally, cooking equipment, such as steamers and fryers, plays a vital role in transforming raw ingredients into consumable products, enhancing flavors and textures.

Another important category is packaging machinery, which is essential for preserving food quality and extending shelf life. This equipment varies from simple vacuum sealers to advanced multi-head scale packers, each designed to meet different production volumes and packaging requirements. Moreover, conveyor systems are vital in streamlining the workflow within a processing facility, allowing for efficient movement of products between various stages. Understanding these different types of food processing machinery will enable businesses to make informed decisions that align with their production goals and operational capacities.

When selecting food processing machinery, evaluating key features and specifications is crucial to optimizing performance and ensuring that equipment aligns with your business needs. According to a report from Grand View Research, the global food processing equipment market is projected to reach $83 billion by 2027, driven by advancements in technology and rising demand for processed foods. In this competitive landscape, businesses must prioritize features such as efficiency, durability, and ease of maintenance in their equipment decisions.

One essential specification to consider is the machine's output capacity. The right machinery should be able to handle your production volume without compromising on quality. For instance, a manufacturer should assess their daily processing needs—if the demand exceeds 2,000 kilograms per hour, investing in high-capacity equipment becomes necessary to meet targets effectively. Additionally, features like automation and integration with existing systems can greatly enhance operational efficiency and reduce labor costs—industry estimates suggest that automation can increase throughput by up to 30%.

Furthermore, compatibility with food safety standards should not be overlooked. Inspection by regulatory bodies has become more stringent; thus, machinery designed with easy cleaning and sanitization in mind can minimize downtime while maintaining compliance. Data from industry analysts indicate that food recalls due to safety issues are significantly reduced by employing equipment that adheres to rigorous hygiene practices. Therefore, making informed decisions based on these evaluated features will not only streamline production but also safeguard your business’s reputation and financial health in the long run.

When evaluating food processing machinery, a critical aspect to consider is the cost-effectiveness and overall return on investment (ROI). According to the Food Processing Machinery Market Report 2022, businesses that strategically invest in advanced processing equipment can experience significant operational efficiencies, reducing costs by an estimated 20-30% over five years. This reduction is primarily due to increased automation and improved workflow, which streamline production processes and minimize labor costs.

To accurately assess ROI, it's essential to analyze not only the initial purchase price but also the long-term savings derived from enhanced productivity and reduced waste. A study conducted by the International Society of Automation indicated that facilities implementing modern machinery could improve their yield by up to 15%, showcasing the importance of making informed decisions when choosing equipment. Furthermore, businesses should consider the maintenance and energy costs associated with various machinery options, as these can dramatically impact the bottom line and continue to influence ROI long after the machinery has been acquired.

When selecting food processing machinery for your business, compliance with industry standards and safety regulations is paramount. These regulations, which vary by region and type of food product, are designed to safeguard public health and ensure the safety of food production processes. Understanding the relevant certification requirements and safety measures that machinery must meet is essential before making any purchase decision. This not only protects consumers but also helps your business avoid potential legal issues that could arise from non-compliance.

Moreover, investing in equipment that aligns with industry standards can enhance the efficiency and reliability of your operations. Properly certified machines often come with features that promote safe processing, such as hygienic designs, easy-to-clean surfaces, and built-in safety mechanisms. Additionally, ensuring that the machinery adheres to regulations can position your company as a trustworthy entity in the eyes of both regulators and customers, thereby increasing your competitive advantage in the market. By prioritizing compliance when selecting food processing equipment, you can streamline your operations while maintaining a strong commitment to food safety.

| Machinery Type | Key Features | Compliance Standards | Safety Regulations | Capacity (kg/hr) | Energy Consumption (kWh) |

|---|---|---|---|---|---|

| Conveyor Belt | Modular design, adjustable speed | ISO 9001 | OSHA Standards | 500 | 1.5 |

| Mixer | Stainless steel, variable speed control | HACCP | ANSI Standards | 300 | 2.0 |

| Packaging Machine | Automated sealing, adjustable settings | FDA Regulations | CE Marking | 800 | 3.5 |

| Grinder | High-speed operation, various settings | ISO 22000 | NFPA Standards | 400 | 2.2 |