- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

In today's competitive business landscape, selecting the appropriate processing machinery is crucial for operational efficiency and profitability. According to a recent report by the Freedonia Group, the U.S. market for processing equipment is expected to reach nearly $32 billion by 2025, driven by advancements in technology and increased demand across various sectors, including food and beverage, pharmaceuticals, and plastics. This underscores the importance of businesses understanding their specific requirements to make informed decisions that align with their growth strategies.

Moreover, a study conducted by MarketsandMarkets highlights that the global processing machinery market is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2028. The rise in automation and the integration of IoT in manufacturing processes are significant contributors to this trend, offering opportunities for businesses to enhance their production capabilities. As companies look to scale their operations, investing in the right processing machinery not only improves efficiency but also positions them competitively in their respective markets. Therefore, understanding the nuances of processing machinery options is vital for any business aiming for sustainable growth and innovation.

When selecting processing machinery for your business, understanding your specific requirements is crucial. Start by assessing the scale and scope of your operations. Consider the type of products you will be processing, the expected volume, and any specific features or capabilities that would enhance productivity. This foundational understanding will guide you in narrowing down your options, ensuring you choose machinery that aligns with your business goals.

**Tip:** Create a detailed checklist of your needs before beginning the search for machinery. Include factors such as production capacity, energy efficiency, ease of operation, and maintenance requirements. This will help you make an informed decision and focus on what truly matters for your business.

Another key factor is to analyze the workflow of your operations. The machinery you select should integrate seamlessly into your existing processes. Evaluate how different machines will affect your production timeline and the overall efficiency of your operations. If possible, gather feedback from your team about their preferences and insights on machinery that may enhance their workflow.

**Tip:** Consider conducting a trial run or demo with potential machinery to see how it performs in real-world conditions. This hands-on approach can provide valuable insights and help you make a confident choice tailored to your specific business scenario.

When evaluating different types of processing machinery for your business needs, it is crucial to understand the unique features and capabilities of each option. Processing machinery can range from simple manual devices to complex automated systems, each designed for specific tasks such as cutting, mixing, or packaging. Start by categorizing machinery based on the primary functions you require. For example, if your business involves food production, you may need machines that target food safety and hygiene standards, while a manufacturing enterprise might prioritize precision and speed.

Another important factor to consider is the scalability and flexibility of the machinery. As your business grows, so too will your processing needs. Selecting equipment that can adapt to varying production volumes or that can be easily upgraded will save time and resources in the long run. Moreover, evaluate the ease of maintenance and user-friendliness of the machinery, as these elements can significantly impact your operational efficiency and workforce training. By taking the time to carefully assess these aspects, you can choose the right processing machinery that aligns perfectly with your business goals.

| Type of Machinery | Application | Key Features | Estimated Cost | Efficiency Rating |

|---|---|---|---|---|

| Industrial Mixer | Food Processing | High capacity, variable speed | $5,000 - $15,000 | 85% |

| CNC Lathe | Metal Fabrication | Precision cutting, automated | $20,000 - $100,000 | 90% |

| Packaging Machine | Beverage Industry | Automated packing, speed adjustment | $10,000 - $50,000 | 80% |

| Baking Oven | Bakery | Energy efficient, multi-functional | $15,000 - $30,000 | 88% |

| Extruder | Plastic Processing | Continuous operation, versatility | $25,000 - $70,000 | 92% |

When selecting processing machinery for your business, understanding the key features that meet your specific operational needs is critical. A recent industry report from Smith & Jones Analytics indicates that 75% of businesses experienced enhanced efficiency after upgrading their processing equipment. One major feature to consider is the machinery’s versatility; equipment capable of handling a range of products not only reduces costs associated with purchasing multiple machines but also allows for quicker adaptation to market changes.

Another essential aspect to focus on is automation capabilities. Automation can significantly improve production rates and reduce labor costs. Data from the International Robotics Federation shows that companies adopting automated processing technologies have seen productivity increases of up to 30%. Additionally, it's vital to assess the machine's energy efficiency ratings. Energy-efficient equipment not only mitigates operational costs but also supports sustainability efforts, which is increasingly becoming a priority for consumers and regulatory bodies alike.

Tips: Always evaluate the total cost of ownership, which includes maintenance and operation costs, not just the purchase price. Consider leveraging industry partnerships and attending trade shows to gather hands-on experiences and insights about different processing technologies. Lastly, consult user reviews and case studies to gauge the real-world performance of various equipment options.

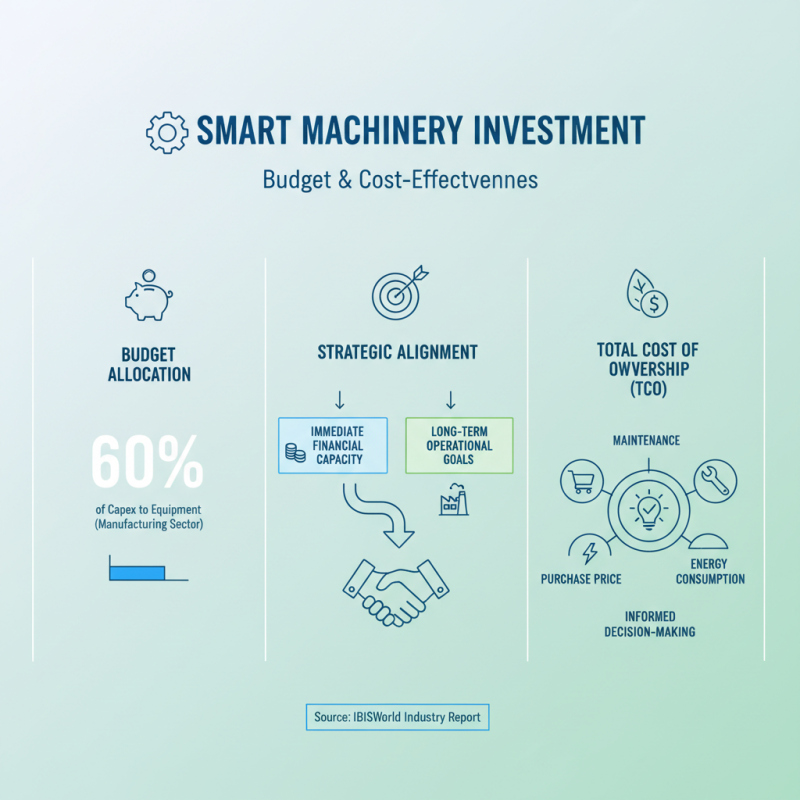

When considering the purchase of processing machinery for your business, assessing the budget and cost-effectiveness is paramount. According to a recent industry report from IBISWorld, businesses in the manufacturing sector allocate approximately 60% of their capital expenditures to equipment acquisition. This figure emphasizes the importance of a well-planned budget that aligns not only with immediate financial capacity but also with long-term operational goals. Understanding the total cost of ownership (TCO), which encompasses purchase price, maintenance, and energy consumption, can greatly influence the decision-making process.

Moreover, a study by Deloitte highlights that companies investing in more advanced and efficient machinery can achieve up to a 20% reduction in operational costs over a five-year period. This reduction is primarily attributed to lower energy requirements and decreased machine downtime. By carefully analyzing cost-effectiveness and projecting the potential savings that new machinery can provide, businesses can ensure that they are making informed decisions that support their growth and sustainability objectives. Adopting a forward-thinking approach emphasizes not just the initial purchase price but also how the machinery will contribute to overall efficiency and profitability in the long run.

When selecting processing machinery for your business, maintenance and support are critical factors that can significantly impact your operational efficiency and bottom line. According to a 2022 industry report by the Manufacturing Excellence Group, approximately 20% of a company's production downtime is attributable to equipment failure. Therefore, it is essential to evaluate the maintenance requirements of any machinery considered for purchase. Machines that are complicated to maintain can increase labor costs and equipment downtime, adversely affecting productivity.

Additionally, effective support systems from manufacturers can ensure that your machinery remains operational with minimal disruption. A survey conducted by the Equipment Manufacturers Association in 2023 found that companies that invest in strong after-sales support experience 15% lower operational costs and 30% higher equipment uptime. Understanding the warranty terms, availability of spare parts, and level of technical support can save businesses both time and money. Prioritizing these considerations not only helps in selecting the right machinery but also ensures sustainability and reliability in your manufacturing processes.