- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

Choosing the right processing machinery is a critical decision that can significantly impact the efficiency and profitability of your business. According to a recent report by Market Research Future, the global processing machinery market is expected to grow at a CAGR of 6.2% from 2021 to 2027, reaching a valuation of over $150 billion by the end of the forecast period. This growth reflects the increasing demand across various industries, including food processing, pharmaceuticals, and packaging, underscoring the importance of selecting machinery that aligns with specific operational needs.

Expert insights in the processing machinery sector emphasize the importance of tailored solutions. Dr. Emily Chen, a leading industry analyst, states, “Investing in the right processing machinery not only enhances production efficiency but also ensures compliance with industry standards, ultimately leading to greater customer satisfaction.” This highlights the necessity for businesses to not only focus on cost but also on how the machinery can integrate into their existing processes and meet future demands. Understanding these dynamics will empower companies to make informed choices that drive growth and sustainability in an increasingly competitive landscape.

When selecting processing machinery for your business, it's crucial to begin by thoroughly understanding your specific requirements. Start by analyzing the nature of your operations—what products or materials will you be processing? Consider the scale of production you aim to achieve, as this will directly influence the type and capacity of machinery you need. For instance, high-volume production may require more advanced automation, while smaller operations might benefit from versatile, multi-functional equipment.

Next, evaluate the technical specifications that align with your goals. This includes considering factors such as processing speed, energy efficiency, maintenance requirements, and adaptability for future needs. Additionally, think about the level of support and training provided by suppliers, as having accessible expertise can significantly ease the integration of new machinery into your workflow. By clearly defining your business's priorities—whether they be cost-effectiveness, durability, or scalability—you can make a more informed decision that will support your growth and enhance operational efficiency.

When selecting processing machinery for your business, it is essential to understand the various types available to meet your specific needs. Processing machinery can be broadly categorized into several types, including mixers, grinders, conveyors, and packaging equipment. Mixers are integral for blending ingredients uniformly, while grinders are essential for reducing the size of the materials. Both play a crucial role in ensuring quality and consistency in production processes.

Conveyor systems, on the other hand, enhance efficiency by facilitating the movement of materials between different stages of production. They help streamline workflows and minimize manual labor. Additionally, packaging machinery is vital for preparing finished products for distribution, ensuring proper sealing and labeling. By familiarizing yourself with these categories, you can make informed decisions about which processing machinery aligns best with your operational requirements, ultimately contributing to the overall effectiveness and productivity of your business.

When evaluating the cost versus benefits of processing machinery for your business, it's essential to conduct a thorough analysis to ensure you make an informed decision. Begin by identifying your specific business needs, which will vary based on the type of products you offer and the scale of your operations. Consider both the initial investment and the long-term operational costs associated with each option. This approach will provide a clearer picture of the potential return on investment (ROI).

Tip: Perform a total cost of ownership (TCO) analysis to account for all costs, including maintenance, energy consumption, and labor. This will help you gauge whether the upfront cost aligns with your budget while also projecting future expenses and savings.

Additionally, it's crucial to assess the efficiency and reliability of the machinery. Compare different options not just on price but also on how each machine performs under various conditions. The benefits of increased production speed or reduced downtime can significantly outweigh minor upfront costs.

Tip: Seek feedback from existing users of the machinery you are considering. Their experiences can provide valuable insights into operational efficiency and longevity, helping you weigh the prospective benefits more accurately against the costs.

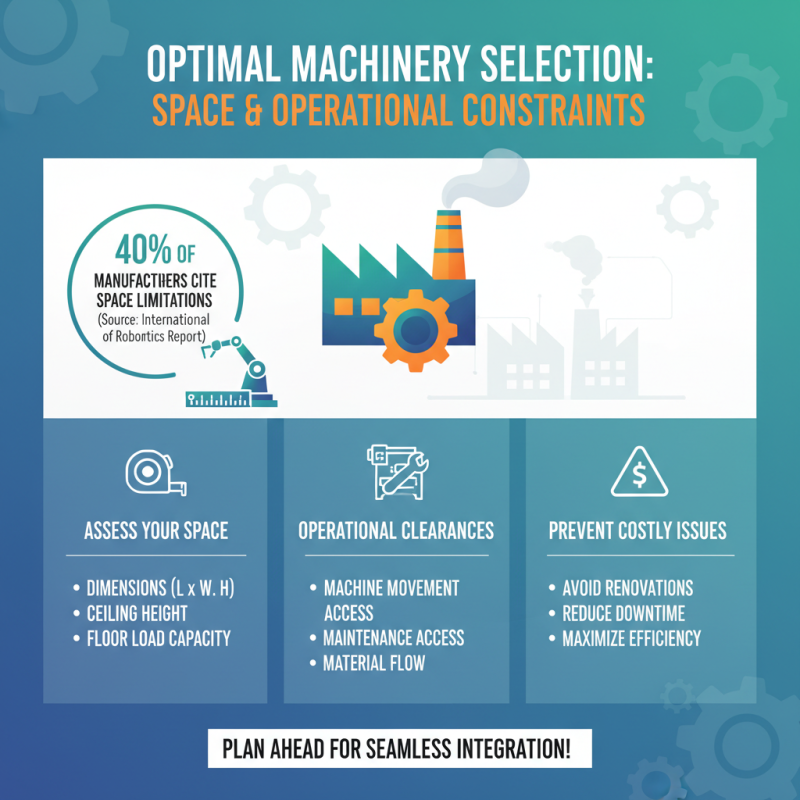

When selecting processing machinery for your business, assessing space and operational constraints is crucial to ensure optimal performance and efficiency. According to a report by the International Federation of Robotics, nearly 40% of manufacturing companies cite space limitations as a significant challenge when integrating new machinery. Understanding the dimensions of your workspace, including ceiling height, floor load capacity, and necessary clearances for operation and maintenance, is essential. This evaluation prevents costly adjustments or renovations that could arise from underestimating your facility's capacity to host new equipment.

Operational constraints also play a pivotal role in machinery selection. A survey conducted by the Manufacturing Institute highlights that about 55% of manufacturers face limitations related to workflow and process integration when considering new technology. Companies must analyze their production processes to determine how new machinery can fit into existing workflows. Factors such as compatibility with current systems, required training for staff, and the potential for future scalability must be taken into account. By conducting a thorough assessment of both space and operational limitations, businesses can make informed decisions that enhance productivity and support long-term growth.

When selecting processing machinery for your business, researching suppliers is a critical step. Start by identifying multiple potential suppliers and assessing their industry reputation. Look for reviews and testimonials to gauge customer satisfaction. A reliable supplier should not only provide high-quality machinery but also demonstrate a commitment to customer service. Pay attention to their communication style and responsiveness, as this can be indicative of the support you will receive throughout your business relationship.

After-sales support is equally important in your decision-making process. Inquire about the types of support offered, including warranty terms, maintenance services, and availability of spare parts. A strong after-sales support system can prevent costly downtime and ensure smooth operations in your business. Additionally, consider whether the supplier provides training for your staff on operating and maintaining the machinery, as this can greatly affect overall efficiency and productivity. By thoroughly researching suppliers and evaluating their after-sales support, you can make an informed choice that aligns with your business needs.

| Machinery Type | Supplier Evaluation Criteria | After-Sales Support Offered | Average Price Range |

|---|---|---|---|

| Packaging Machinery | Quality Certifications, Customer Reviews, Service Response Time | Installation, Maintenance, Spare Parts Availability | $10,000 - $50,000 |

| CNC Machining Centers | Technical Support Availability, Training Programs, Warranty Terms | Operator Training, 24/7 Support, Remote Troubleshooting | $30,000 - $200,000 |

| Material Handling Equipment | Industry Experience, Customization Options, Delivery Time | Preventive Maintenance, Technical Assistance, Replacement Parts | $5,000 - $75,000 |

| Food Processing Machinery | Compliance with Food Safety Standards, Customer Testimonials, Technical Specs | Hygiene Training, Onsite Support, Parts Inventory | $15,000 - $120,000 |

| Printing Machinery | Print Quality, Speed, Energy Efficiency | Software Updates, Operator Support, Maintenance Contracts | $20,000 - $150,000 |