- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

In the meat processing industry, choosing the right equipment is crucial. According to a recent industry report by IBISWorld, the global meat processing market is expected to reach $485 billion by 2024. This growth highlights the need for efficient meat processing equipment in businesses of all sizes. Quality machinery can enhance productivity and maintain product safety, but it’s not always easy to choose.

When selecting meat processing equipment, consider factors like capacity and versatility. Equipment should cater to various meat types and processing techniques. However, overlooking maintenance needs can lead to inefficiencies and increased costs. A misstep here can hinder operations and reduce profit margins.

Many businesses also fail to evaluate the latest technologies. Automation and smart systems are becoming essential in modern meat processing. Implementing advanced meat processing equipment can streamline processes, saving time and labor. Nevertheless, balancing upfront costs with long-term benefits is a constant challenge. A careful approach can set your business up for success in a competitive market.

When choosing meat processing equipment, understanding the various types available is crucial. Equipment varies significantly. You may need grinders, slicers, and vacuum sealers. Each type serves a distinct purpose within your processing operations. For example, grinders turn large cuts of meat into desired textures, while slicers help in producing uniform slices for retail.

Consider the capacity of each piece. Is it suitable for your business size? It’s essential to match your needs with the equipment capabilities. You may find some machines oversized for your operations. This could lead to inefficiency. A well-sized machine saves space and reduces operational costs.

Tips for selecting equipment include assessing material quality. Stainless steel is often the best choice, as it’s easy to clean and durable. Always check for safety features. If the equipment is difficult to operate, reconsider your options. Equipment that does not meet safety standards can lead to accidents and injuries in the workplace. Pay attention to user reviews and maintenance requirements too. Some equipment may require more upkeep than you anticipated. Reflect on long-term costs versus initial investment for better decision-making.

| Equipment Type | Description | Applications | Key Features | Considerations |

|---|---|---|---|---|

| Meat Grinders | Used for grinding raw meat into desired texture. | Ground meat products like sausages and burger patties. | Variable grind sizes, easy to clean, heavy-duty motor. | Power requirements, maintenance, and capacity. |

| Slicers | Cuts meat into uniform slices for packaging. | Deli meats, bacon, and steaks. | Adjustable slicing thickness, safety features, durable blades. | Size of meat cuts and speed of operation. |

| Mixers | Combines meat with other ingredients for seasoning. | Sausage production and marinated meats. | High mixing efficiency, easy cleanup, large capacity. | Consistency of mix and motor power. |

| Stuffers | Fills casings with prepared meat mixtures. | Sausages, hot dogs, and other encased meats. | Varied stuffing speeds, different size tubes. | Hygiene and ease of filling process. |

| Vacuum Sealers | Removes air from bags to preserve meat freshness. | Long-term storage and food preservation. | Durable sealing, adjustable vacuum strength. | Bag compatibility and sealing speed. |

| Smokehouses | Cooks and preserves meat using smoke. | Smoked meats like ham and sausage. | Temperature control, smoke options, capacity. | Size, fuel type, and ease of cleaning. |

When choosing meat processing equipment, several key factors deserve your attention. Understanding your production capacity is crucial. Determine how much meat you will process daily. This number will guide you in selecting equipment that meets your needs. Too small, and you’ll struggle to keep up. Too large, and you waste resources.

Quality is another critical point. Look for equipment that ensures hygiene and efficiency. Stainless steel is often preferred. It’s easier to clean and less prone to rust. Always check for certifications that guarantee compliance with health standards. This ensures safety and quality, protecting your business reputation.

Consider the maintenance aspect as well. Equipment will require upkeep. Factoring in maintenance costs helps avoid unexpected expenses later. Buying durable equipment may have a higher upfront cost, but it often pays off over time. Regular maintenance can prolong the lifespan of your machinery.

Don't forget about training staff. Equipment is only as good as the operators. Invest time in training them. Efficiently trained staff can avoid mishaps that may lead to downtime. Communication about preferences and needs helps ensure everyone is on the same page.

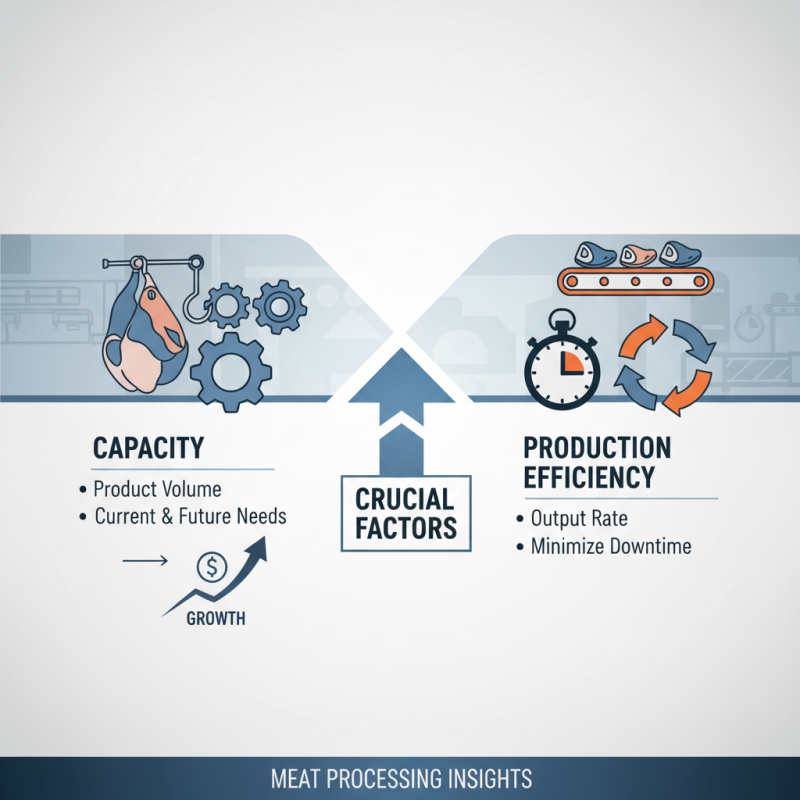

When evaluating meat processing equipment, capacity and production efficiency are crucial factors. A machine’s capacity defines how much product it can handle. Consider your current needs and future growth. Will you expand soon? A machine that meets today’s requirements may fall short tomorrow.

Next, analyze production efficiency. Efficiency impacts your bottom line. A high-output machine saves time but might consume more energy. Look for a balance. Regular maintenance will ensure longevity but can also slow down output.

Tips: Prioritize machines designed for easy cleaning. Hygiene is non-negotiable in meat processing. Remember, downtime can be costly. A backup plan for equipment failure is wise. Avoid the trap of overestimating your production capacity. Always base decisions on realistic assessments.

When selecting meat processing equipment, safety standards are paramount. According to the USDA, strict compliance with regulations ensures food safety. Failing to adhere can lead to serious consequences. In fact, improper equipment can result in contamination, causing health risks to consumers and significant financial losses.

Compliance with safety standards involves knowing local and federal regulations. Equipment must meet guidelines established by the FDA and USDA to operate legally. For instance, the machinery should be easy to clean and maintain. Regular inspections are necessary to ensure they meet safety benchmarks. Many businesses overlook this necessity, potentially jeopardizing their operations.

Investing in equipment that meets these safety standards is a long-term strategy. Non-compliant equipment may save costs upfront but can lead to bigger issues later. Furthermore, inaccurate temperature controls can compromise product integrity. Reports from industry experts indicate that up to 30% of meat product recalls are linked to processing non-compliance. It's vital for businesses in this sector to prioritize safety to maintain consumer trust.

When investing in meat processing equipment, budgeting is key. Reports indicate that a small to medium-sized meat processing plant can expect to spend between $150,000 to $500,000 on equipment alone. It’s essential to identify the core pieces needed, like grinders, saws, and slicers. Prices can vary significantly based on capacity and functionality. Prioritizing essential machinery can help control initial costs.

Cost analysis doesn’t stop at the initial purchase. Ongoing expenses, such as maintenance and energy consumption, also come into play. For example, industry studies reveal that an efficient meat grinder can save businesses up to 20% in energy costs. Yet, the initial investment in energy-efficient equipment is often higher. Not every piece of equipment provides a clear long-term ROI, making it essential to evaluate performance versus expenditure carefully.

Additionally, consider depreciation in your financial planning. Some equipment loses value quickly, while others retain it better. Industry averages show that meat processing machines depreciate by about 10-20% annually. Aim for a balanced approach, where quality meets budget without sacrificing efficiency. This can be challenging but will lead to better long-term operating costs. Reflecting on these aspects is crucial in making an informed decision.