- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

The seafood industry has undergone a significant transformation in recent years, primarily driven by advancements in fish processing equipment. As technology continues to evolve, the efficiency and sustainability of seafood harvesting and preparation are revolutionized, enabling producers to meet increasing consumer demands while minimizing waste. "The development of modern fish processing equipment is crucial for enhancing the quality and shelf life of seafood, ensuring that consumers receive the freshest products possible," says Dr. Emily Johnson, a leading expert in aquaculture and food technology.

With innovations ranging from automated filleting machines to advanced freezing techniques, fish processing equipment plays a vital role in streamlining production processes and maintaining the integrity of the product. These technological enhancements not only improve operational efficiency but also contribute to better hygiene and food safety standards, which are paramount in the seafood industry. As we delve deeper into the impact of fish processing equipment, it becomes evident that these advancements not only benefit producers but also elevate the overall consumer experience by providing higher quality seafood options.

Fish processing equipment encompasses a variety of tools and technologies designed to improve the efficiency and quality of seafood processing. This equipment can range from simple filleting machines to complex automated systems that handle multiple stages of processing, including cleaning, packaging, and freezing.

According to a report by Research and Markets, the global fish processing equipment market is expected to reach USD 18.5 billion by 2026, reflecting a growing demand for more efficient processing methods in the seafood industry.

One of the key advancements in fish processing equipment is the introduction of automated processing lines, which significantly reduce labor costs and processing times. For instance,

a study published in the Journal of Food Engineering highlights that automation can increase processing efficiency by up to 30%, allowing seafood companies to meet rising consumer demand without compromising on product quality. Additionally, modern fish processing equipment often incorporates advanced technologies such as sensors and artificial intelligence, enabling real-time monitoring of production processes and maintaining strict food safety standards.

Furthermore, the integration of sustainability practices into fish processing equipment has gained traction. Equipment designed for energy efficiency and waste reduction contributes to a more sustainable seafood industry. A report by the Food and Agriculture Organization emphasizes that efficient processing can minimize bycatch and waste, helping to preserve marine ecosystems while meeting the needs of a growing global population. As the seafood market continues to evolve, the role of fish processing equipment will undoubtedly become even more critical in ensuring the industry's sustainability and resilience.

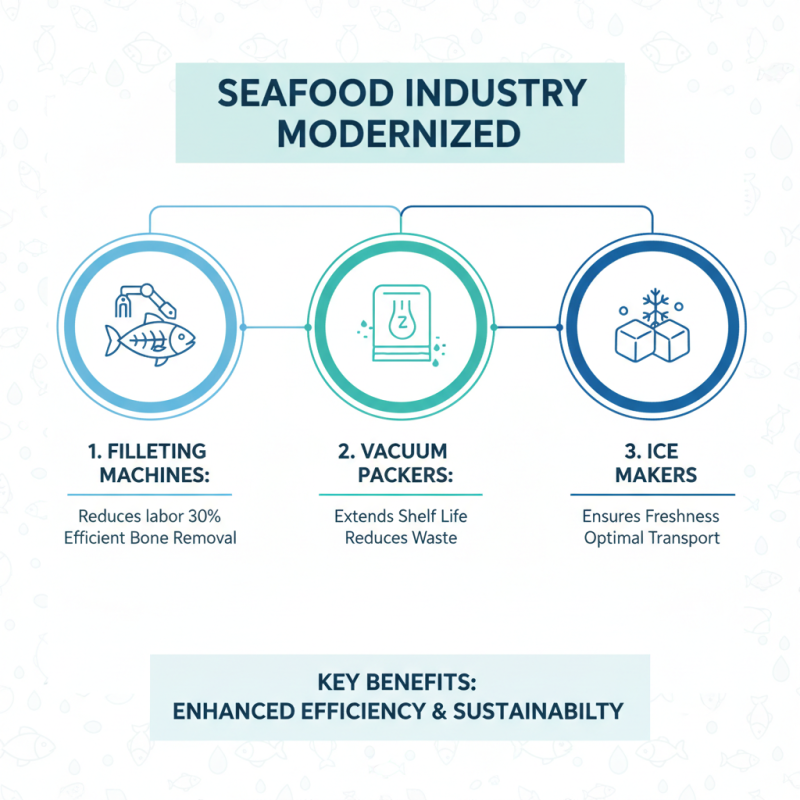

Fish processing equipment plays a crucial role in modernizing the seafood industry, significantly enhancing efficiency and sustainability. Essential components include filleting machines, vacuum packers, and ice makers. Filleting machines streamline the process of removing bones and skin, reducing labor costs by up to 30% according to industry reports. Furthermore, vacuum packers extend shelf life, keeping seafood products fresher and reducing waste. Ice makers are vital for maintaining optimal temperatures during transport and storage, ensuring that high-quality seafood reaches consumers.

Understanding these key components can help stakeholders make informed decisions in their operations. For instance, investing in high-quality filleting equipment can lead to a 20% increase in production capacity, positively impacting profit margins. Additionally, implementing efficient vacuum packing systems contributes to a decrease in spoilage rates, which can be as high as 10% in traditional setups.

**Tips:** When selecting fish processing equipment, consider the volume of seafood processed and the specific capabilities of each machine. Regular maintenance is essential to extend the lifespan of these machines and maintain high operational efficiency. Investing in reliable ice-making solutions can also prevent costly losses during peak seasons.

Technological advancements in fish processing have significantly transformed the seafood industry, improving efficiency, sustainability, and product quality. Innovations such as automated sorting, advanced freezing techniques, and real-time monitoring systems have streamlined operations, allowing processors to handle larger volumes with greater precision. According to a report from MarketsandMarkets, the global fish processing equipment market is projected to reach USD 27.9 billion by 2026, driven by these technological improvements.

One notable advancement is the use of artificial intelligence (AI) in quality control and sorting processes. AI-powered systems can analyze fish characteristics and detect anomalies, ensuring that only the highest quality products reach consumers. In addition, advancements in cold chain technologies have enhanced the ability to preserve freshness from catch to consumer, reducing spoilage and waste. The Food and Agriculture Organization (FAO) estimates that better handling practices could potentially lower fish spoilage rates by up to 30%, significantly benefiting both the economy and the environment.

Moreover, the integration of IoT (Internet of Things) devices in processing facilities allows for real-time data collection and analysis, optimizing production workflows. By monitoring variables such as temperature and humidity throughout the processing chain, companies can ensure compliance with safety standards and improve operational efficiency. A study from Technavio highlights that the adoption of IoT in seafood processing can reduce operational costs by approximately 25%, underscoring its potential impact on the industry. These technological advancements are not just changing how fish is processed but are also setting new standards for quality and sustainability in the seafood supply chain.

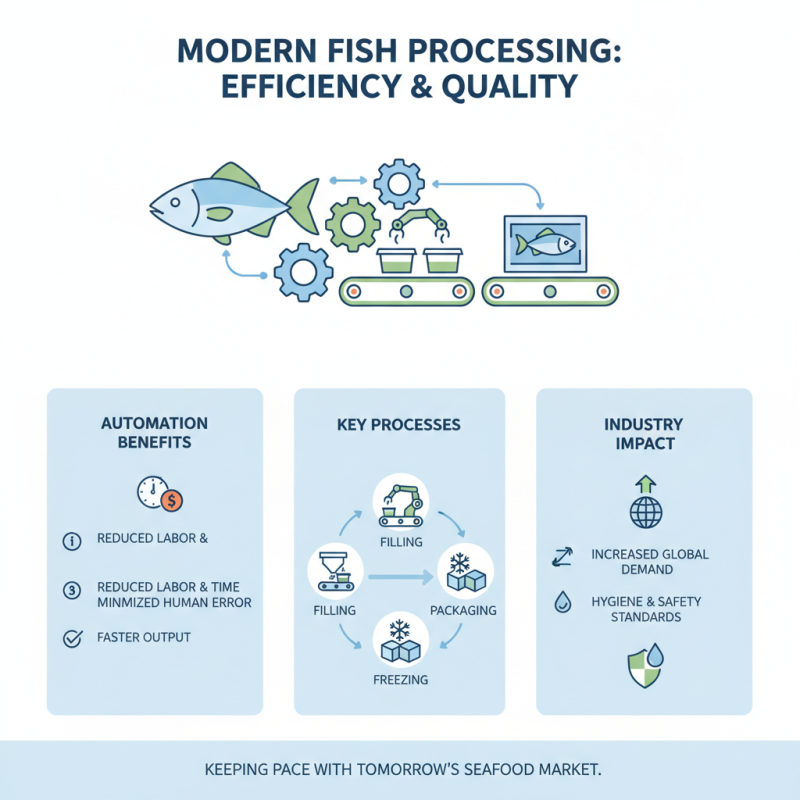

Fish processing equipment plays a crucial role in enhancing efficiency and quality within the seafood industry. By automating various processes such as filleting, packaging, and freezing, these machines significantly reduce the time and labor costs associated with seafood preparation. This automation not only ensures faster output but also minimizes human errors, leading to a more consistent and higher-quality product. As the demand for seafood grows globally, the adoption of advanced fish processing equipment helps businesses keep pace with market needs while maintaining stringent hygiene and safety standards.

Furthermore, fish processing equipment contributes to better resource management and sustainability in the industry. By maximizing the yield from each fish and reducing waste, processors can operate more sustainably. Advanced technologies, such as cold storage and vacuum packing, extend the shelf life of seafood products, ensuring that they reach consumers in optimal condition. This not only benefits consumers but also helps companies meet regulatory requirements related to food safety and quality. Overall, the investment in modern fish processing equipment is essential for any seafood business aiming to thrive in a competitive market while promoting sustainability and responsible practices.

The seafood industry is undergoing a significant transformation with the advent of advanced fish processing technology. One of the most prominent future trends is the integration of automation and robotics in processing facilities. These technologies not only enhance operational efficiency but also improve product quality and reduce waste. Automated systems can handle tasks such as sorting, filleting, and packaging with precision, reducing the need for manual labor and minimizing human error. This shift toward automation allows for higher throughput and consistency in processing, meeting the growing demand for seafood globally.

Another key trend is the adoption of sustainable practices through innovative processing solutions. As consumers become increasingly aware of environmental issues, fish processing equipment is evolving to support sustainable fishing and aquaculture. Technologies such as water recycling systems and energy-efficient machinery are becoming standard in modern processing plants. Additionally, advancements in cold chain logistics ensure that seafood is maintained at optimal temperatures throughout its journey from ocean to table, thereby preserving freshness and reducing spoilage. This focus on sustainability not only addresses consumer preferences but also aligns with regulatory demands for responsible seafood sourcing.

| Equipment Type | Function | Impact on Industry | Future Trends |

|---|---|---|---|

| Filleting Machines | Automates the cutting of fish into fillets | Increases processing speed and reduces labor costs | Integration with AI for precision cutting |

| Ice Machines | Produces ice to keep fish fresh | Enhances product quality and extends shelf life | Smart technology for ice production tracking |

| Packing Machines | Packages fish products for shipment | Improves efficiency and reduces waste | Sustainable packaging solutions |

| Eviscerating Machines | Removes internal organs from fish | Enhances food safety and processing speed | Robotics for improved handling |

| De-watering Machines | Removes excess water from fish | Improves processing efficiency | Energy-efficient models |