- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

In the modern culinary landscape, businesses in the food industry rely heavily on a range of essential tools and materials to ensure efficiency, safety, and quality in their operations. Among these critical resources are food processing supplies, which encompass everything from basic utensils to advanced machinery that streamline food preparation, preservation, and packaging processes. The importance of these supplies cannot be overstated, as they directly impact the ability of businesses to provide consistent, high-quality products to their customers.

Food processing supplies are more than just equipment; they play a vital role in maintaining food safety standards and meeting regulatory requirements. Investing in the right supplies allows businesses to optimize their workflow, reduce waste, and enhance the overall customer experience. Furthermore, as consumer demands evolve and sustainability becomes a key concern, the importance of using appropriate food processing supplies that align with environmentally friendly practices is increasingly recognized.

In summary, understanding food processing supplies and their significance is crucial for any business operating within the food sector. By equipping themselves with the right tools and materials, businesses can navigate the complexities of food production while ensuring a safe and enjoyable experience for their customers.

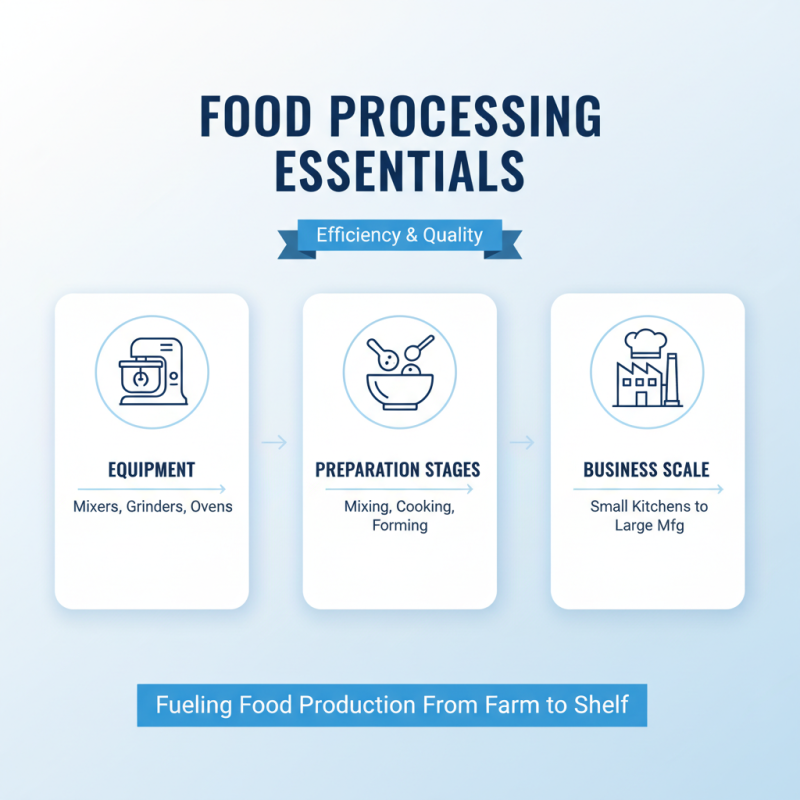

Food processing supplies encompass a wide range of tools, equipment, and raw materials that are essential for transforming

raw ingredients into finished food products. This includes everything from mixing and cooking

equipment to packaging materials and preservation aids. The scope of food processing supplies is vast, catering to different sectors

within the food industry, such as restaurants, food manufacturers, and catering services. Properly investing in these supplies ensures

efficiency, safety, and consistency in food production.

When selecting food processing supplies, businesses should focus on durability and functionality.

High-quality equipment can withstand the rigors of daily use, minimizing downtime and maintenance costs. It's also important to

consider the scalability of these supplies, as businesses may need to expand their operations in the future.

Tips: Always keep your food processing equipment clean and well-maintained to ensure

food safety and compliance with health regulations. Additionally, regularly reviewing your supply chain can help you find the

best sources for ingredients and materials, saving costs while maintaining quality.

In the food processing industry, various supplies are essential to ensure efficiency and quality. Common types of food processing supplies include equipment such as mixers, grinders, and ovens. These tools help in the preparation, mixing, and cooking of food products, making them crucial for businesses ranging from small kitchens to large-scale manufacturing facilities.

In addition to processing equipment, storage solutions are vital. Items like containers, refrigeration units, and shelving systems play a significant role in maintaining the integrity of food products while ensuring compliance with health regulations. Moreover, packaging supplies, including bags, boxes, and labels, are essential for branding and protecting food items during transport and display.

Tips: When selecting food processing supplies, consider the specific needs of your business. Investing in quality equipment can lead to long-term savings by reducing maintenance costs and increasing efficiency. Additionally, staying up-to-date with industry trends can help businesses choose the right supplies that enhance productivity and meet consumer demands.

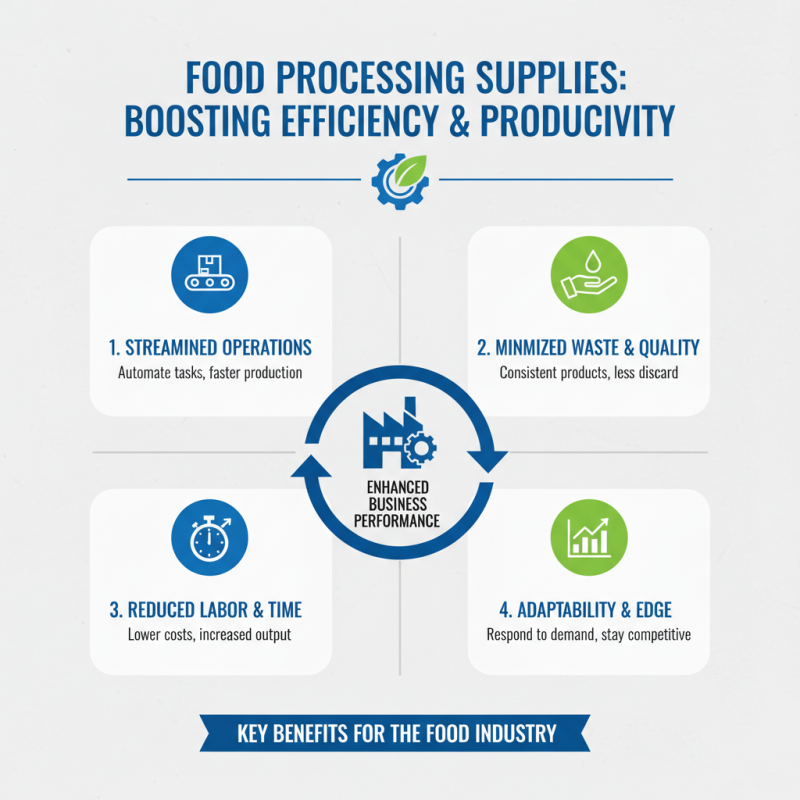

Utilizing food processing supplies is fundamental for businesses in the food industry, as it enhances efficiency and ensures product quality. One of the key benefits of these supplies is the consistency they provide in food production. By using standardized equipment and ingredients, businesses can maintain uniformity in taste and texture, which is vital for customer satisfaction and brand reputation. This reliability allows companies to meet consumer expectations and streamline their operations, thus improving overall productivity.

Another significant advantage of food processing supplies is the ability to meet safety regulations and food quality standards. In today’s market, consumers are increasingly concerned about food safety, making compliance with health regulations more critical than ever. By employing appropriate processing supplies, businesses can ensure their products are prepared safely and hygienically, minimizing the risk of contamination. Moreover, investing in high-quality processing tools can lead to reduced waste and increased shelf life of products, ultimately benefiting the bottom line and fostering consumer trust.

| Dimension | Description | Benefit |

|---|---|---|

| Quality Assurance | Food processing supplies help maintain hygiene and quality in food production. | Improves customer satisfaction and reduces waste. |

| Efficiency | Streamlined operations reduce time and labor costs in food preparation. | Increases productivity and profitability. |

| Safety Standards | Ensures compliance with safety regulations and standards. | Minimizes legal risks and enhances brand reputation. |

| Versatility | Wide range of supplies available for different food processing needs. | Allows businesses to diversify products and services. |

| Cost-effectiveness | Bulk purchasing of supplies reduces overall costs. | Enhances savings and increases competitive advantage. |

Food processing supplies play a crucial role in enhancing the efficiency and productivity of businesses within the food industry. These supplies encompass a wide range of tools and equipment designed to streamline operations, minimize waste, and ensure the quality of food products. By utilizing advanced processing equipment, companies can automate repetitive tasks, leading to faster production times and reduced labor costs. This efficiency not only maximizes output but also allows businesses to respond quickly to changing customer demands, thereby maintaining a competitive edge.

Furthermore, the impact of food processing supplies on productivity extends beyond mere speed. High-quality processing equipment improves the consistency and safety of food products, which is vital in meeting regulatory standards and customer expectations. When businesses invest in reliable food processing supplies, they are better equipped to maintain product quality over time, reducing the likelihood of recalls or quality-related issues. This not only fosters customer trust but also boosts overall operational effectiveness, allowing businesses to focus on innovation and expansion within the industry. Ultimately, the right food processing supplies empower companies to operate smoothly and effectively, driving long-term success.

Choosing the right food processing supplies can significantly influence the efficiency and quality of food production. When selecting equipment and materials, it’s essential for businesses to consider various factors such as durability, compliance with safety regulations, and ease of cleaning. According to recent industry reports, the global food processing equipment market is expected to grow significantly, driven by increasing demand for processed foods and stringent food safety standards. Businesses should prioritize supplies that ensure product quality and safety, as these are crucial to maintaining customer trust and adhering to regulatory requirements.

A critical consideration when selecting food processing supplies is the compatibility of materials with specific food types and production processes. For example, some materials may react adversely with certain ingredients, leading to contamination or spoilage. It is advisable to look for non-reactive, food-grade materials that can withstand the rigors of processing without compromising product integrity. Additionally, investing in energy-efficient equipment can not only reduce operational costs but also promote sustainability within the industry.

Tips: Always conduct a thorough analysis of your production needs and the specific requirements of your food products. Engage with suppliers who offer a diverse range of options and are knowledgeable about current industry trends. Regularly assess your equipment for efficiency and compliance with safety standards to ensure optimal performance and quality assurance.