- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

In the evolving landscape of the food processing industry, efficiency is vital for growth and sustainability. John Smith, a leading expert in food technology, emphasizes, "Improving efficiency is not just an option, it's a necessity." This statement underlines the pressure on companies to streamline operations.

The food processing industry faces numerous challenges. Increasing demand for quality products complicates production processes. Companies must balance speed with safety, often leading to trade-offs. Many firms rely on outdated systems that hinder progress.

However, embracing innovative technologies can provide solutions. Automation and data analytics offer new avenues for efficiency. Yet, not every approach guarantees success. Each strategy requires careful evaluation and adaptation. The food processing industry must foster a mindset of continuous improvement to thrive in a competitive environment.

The food processing industry faces significant challenges in efficiency. A report by the Food Marketing Institute highlights that about 70% of food processing firms struggle with time management. Streamlining workflows could reduce production time drastically. Some companies still rely heavily on outdated technologies. Upgrading machinery could save a substantial amount of resources and energy.

Another critical area for improvement is inventory management. According to the Global Food Safety Initiative, about 25% of food waste occurs due to poor inventory practices. Investing in real-time tracking systems can help mitigate this waste. Some businesses report a 20% reduction in spoilage after implementing better tracking. Yet, many firms are still hesitant to adopt these new technologies.

Training employees is often overlooked. A survey indicates that 52% of workers feel they lack adequate training for new systems. Proper training can lead to smoother operations and fewer errors. It is concerning that many organizations fail to prioritize this aspect. Efficiency is not just about technology; it's also about creating a skilled workforce. Addressing these areas can lead to marked improvements in overall productivity.

In the food processing industry, the adoption of advanced technology solutions can significantly enhance efficiency. Automation, for instance, streamlines production lines. Machines can run continuously, reducing human error and increasing output. These systems can monitor quality in real-time, ensuring products meet safety standards. However, integrating these technologies is not always straightforward.

Training staff becomes crucial. They need to understand the new systems. Some may resist change, feeling overwhelmed. It is important to create a culture that embraces technology. Regular training sessions can help ease this transition. Providing hands-on experience allows employees to build confidence.

Data analytics also plays a vital role. Analyzing production data helps identify bottlenecks. However, not all companies utilize these insights effectively. Many still rely on intuition rather than facts. This can lead to wasted resources and time. A shift toward data-driven decision-making could propel the industry forward. Yet, this requires patience and commitment. Each step is part of a larger journey toward greater efficiency.

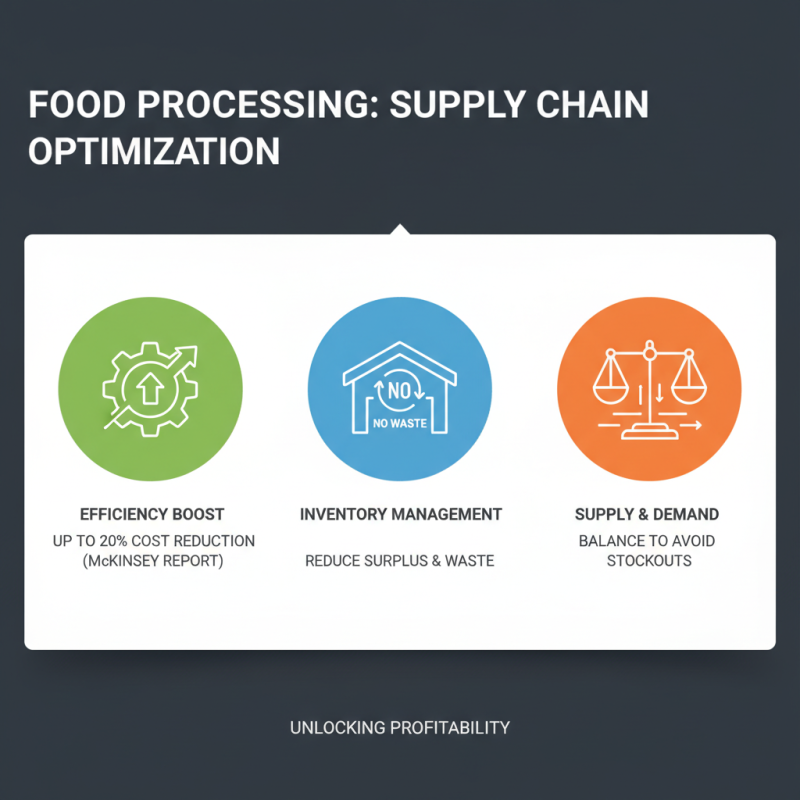

In the food processing industry, effective supply chain management is crucial for enhancing efficiency. A report by McKinsey indicates that optimizing supply chains can reduce operational costs by up to 20%. Companies often miss opportunities in inventory management, leading to surplus stock and waste. Many struggle to balance supply with demand, causing frequent stockouts or overproduction.

Utilizing data analytics can significantly improve resource utilization. By analyzing purchasing patterns and consumer behavior, businesses can forecast demand more accurately. Statistics show that businesses employing advanced analytics experience a 15-20% increase in efficiency. However, implementing these systems requires time and investment, which can deter companies from adopting them.

Training staff to adapt to new technologies is another challenge. Employees may resist change, impacting overall productivity. Addressing this resistance through consistent training programs is essential. Yet, many companies overlook this crucial step. The path to streamlined supply chains isn’t always straightforward, and it demands ongoing reflection and adjustment.

Training and development are essential for optimizing workforce efficiency in the food processing industry. When workers possess the right skills, productivity increases significantly. Developing a skilled workforce is more than just basic training. It requires continuous education and practical experience.

One effective approach is to implement hands-on workshops. These can help employees understand machinery and processes better. Regularly scheduled training sessions can keep everyone updated on new techniques. Workers often have gaps in knowledge. Filling these gaps can enhance their confidence and performance.

Also, encourage a culture of learning. Create opportunities for employees to share insights and ideas. This collaboration can lead to innovative solutions and methodologies that improve operations. Addressing unexpected challenges requires a flexible workforce.

Tips: Offer incentives for workers who complete training programs. This could motivate participation. Conduct surveys to gather feedback on training effectiveness. Adjust your programs based on employee input. Engaging employees in their learning journey can lead to lasting improvements.

Sustainable practices can significantly enhance efficiency in the food processing industry. By reducing waste and energy consumption, companies can cut costs. For instance, implementing recycling programs for materials can reduce landfill use. This not only conserves resources but also minimizes operational expenses.

Using renewable energy sources is another effective strategy. Solar panels or wind turbines can provide clean energy. However, these initiatives often come with high upfront costs. Some companies may struggle to justify the initial investment without seeing immediate returns.

Moreover, water usage is critical in food processing. Implementing water-efficient technologies can save significant amounts. Many companies, though, might hesitate due to the complexity of upgrading systems. There's always a risk in altering established processes. Just focusing on efficiency may overlook the importance of employee training and involvement. Engaging workers is essential for ensuring sustainability goals are met.

| Sustainable Practice | Efficiency Improvement (%) | Cost Reduction (%) | Waste Reduction (%) | Energy Savings (%) |

|---|---|---|---|---|

| Energy Efficient Equipment | 15 | 10 | 5 | 20 |

| Water Recycling Systems | 10 | 8 | 25 | 5 |

| Waste Management Programs | 12 | 15 | 30 | 10 |

| Sustainable Ingredient Sourcing | 8 | 5 | 15 | 3 |

| Process Optimization Technologies | 20 | 12 | 20 | 25 |