- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

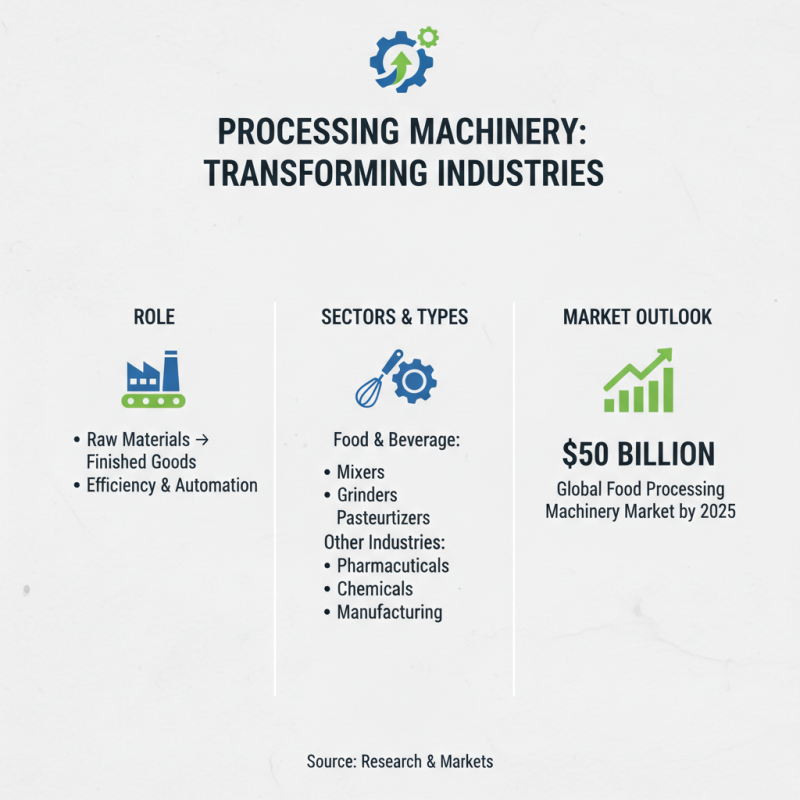

Processing machinery plays a crucial role in the landscape of modern industries, serving as the backbone for a vast array of manufacturing processes. From food production to pharmaceuticals and metalworking, processing machinery is designed to transform raw materials into finished products efficiently and effectively. The versatility and complexity of these machines enable industries to boost productivity, ensure quality control, and optimize workflow, thereby meeting the demands of a fast-paced global market.

In essence, processing machinery encompasses various equipment and technologies that facilitate the conversion of inputs into outputs. This includes systems for mixing, grinding, cutting, and packaging, each tailored to specific industrial needs. As industries continue to evolve, the innovation in processing machinery remains at the forefront, integrating advanced automation, robotics, and data analytics to enhance operational efficiency. Understanding how processing machinery works is vital for industries looking to stay competitive and responsive to ever-changing consumer needs.

Moreover, the strategic implementation of processing machinery not only improves production capabilities but also promotes sustainability by optimizing resource use and minimizing waste. As we delve deeper into the mechanics and applications of processing machinery, we can appreciate its indispensable contribution to the success and advancement of modern industries.

Processing machinery plays a crucial role in modern industries by facilitating the transformation of raw materials into finished products. In an industrial context, processing machinery refers to a range of equipment and tools designed to process different materials through various methods such as cutting, mixing, heating, or shaping. This machinery is essential in sectors like food processing, pharmaceuticals, and manufacturing, where precision and efficiency are vital for maintaining quality and meeting production demands.

When selecting processing machinery, it is important to consider factors such as the type of materials being processed, the desired output, and the operational efficiency of the equipment. Understanding these parameters can significantly enhance productivity and reduce waste.

Tips: Always conduct thorough research on the specifications and capabilities of processing machinery before making a purchase. Keeping up with technological advancements can also help in selecting machinery that offers improved energy efficiency and reduced operational costs. Additionally, ensuring regular maintenance of the machinery will prolong its lifespan and safeguard the quality of the products being manufactured.

| Processing Machinery Type | Primary Function | Industries Served | Energy Source | Automation Level |

|---|---|---|---|---|

| Mixers | Mixing of ingredients | Food & Beverage | Electric | Semi-Automated |

| Conveyors | Transporting materials | Manufacturing | Electric | Fully Automated |

| Filling Machines | Filling products into containers | Pharmaceuticals, Food | Pneumatic | Automated |

| Cutter Machines | Cutting materials into specified sizes | Textiles, Woodworking | Electric | Semi-Automated |

| Packaging Machines | Packaging products for distribution | Food, Consumer Goods | Electric | Fully Automated |

Processing machinery plays a crucial role in various modern industries, facilitating the transformation of raw materials into finished goods. There are several types of processing machinery, each tailored for specific applications. For instance, in the food and beverage sector, processing machinery includes mixers, grinders, and pasteurizers that ensure safety and consistency in production. A report by Research and Markets indicates that the global food processing machinery market is projected to reach $50 billion by 2025, highlighting the significant demand for efficiency and automation in food manufacturing processes.

In the pharmaceuticals and chemical industries, machinery such as reactors, crystallizers, and separators are essential for creating products with precision and reliability. According to a study by Grand View Research, the pharmaceutical processing equipment market is expected to grow at a compound annual growth rate (CAGR) of 6.9% from 2022 to 2030, driven by increasing investments in drug development and the need for advanced manufacturing technologies. These processing machines not only optimize production speed but also enhance product quality, ensuring compliance with stringent regulatory standards.

Similarly, in the textiles and automotive sectors, weaving machines and CNC machining tools are pivotal in delivering innovative solutions. The global textile machinery market size was valued at $20 billion in 2022 and is anticipated to witness a steady increase as manufacturers integrate smart technologies. This evolution in processing machinery underscores the ongoing shift towards automation and advanced manufacturing techniques across diverse industries, ultimately driving productivity and innovation.

Processing machinery plays a vital role in modern industries, employing various mechanisms and functions to streamline production processes. At its core, processing machinery transforms raw materials into finished products, using techniques such as mixing, milling, heating, and packaging. For instance, conveyor belts move materials through different stages, while mixers and grinders prepare inputs for further processing. Each piece of machinery is designed to optimize efficiency, reduce waste, and enhance product quality.

Understanding how processing machinery operates involves a closer look at its components and mechanisms. Most machines work using a combination of mechanical, hydraulic, and pneumatic systems. These systems ensure that materials are handled effectively and safely. Sensors and controls also play an integral role, allowing operators to monitor processes in real-time and make adjustments to enhance performance. This integration of technology not only improves output but also ensures that safety standards are met consistently.

Tips: When implementing processing machinery in your operations, it's crucial to prioritize regular maintenance to avoid downtime. Additionally, investing in operator training can enhance safety and efficiency on the production floor. Regularly evaluating your processes for potential upgrades can further optimize your machinery's performance, leading to increased productivity and reduced operational costs.

Automation plays a pivotal role in modern processing machinery, significantly enhancing efficiency and precision across various industries. By integrating advanced technologies such as robotics, artificial intelligence, and machine learning, manufacturers can streamline their operations, reduce human error, and lower production costs. Automated systems allow for continuous operation without the need for breaks, thereby increasing productivity levels and meeting the ever-growing demand for rapid output.

Moreover, automation in processing machinery leads to improved safety and consistency in production processes. By deploying sensors and monitoring systems, manufacturers can gather real-time data, allowing for immediate adjustments and predictive maintenance. This reduces the likelihood of equipment failure and enhances overall reliability. Furthermore, automation facilitates the customization of products to meet specific consumer demands, enabling manufacturers to remain competitive in a dynamic market landscape. The ability to quickly reconfigure machinery for different tasks positions companies to respond to changing market trends without significant downtime, making automation an integral component of modern processing operations.

The landscape of processing machinery in modern industries is constantly evolving, shaped by numerous challenges and innovative solutions. One significant challenge facing the industry is the increasing demand for efficiency and sustainability. As companies strive to reduce operating costs and minimize their environmental footprint, the need for advanced machinery that can optimize production processes becomes paramount. Innovations such as smart sensors and automation technologies are being implemented to enhance operational efficiency, allowing machinery to adjust in real-time based on demand and resource availability.

Another pressing challenge is the need for adaptability in processing machinery. With rapid technological advancements and shifting market dynamics, industries are required to pivot quickly to meet diverse needs. This has led to the development of modular machinery that can be easily customized or upgraded, ensuring longevity and flexibility in operations. Additionally, advancements in artificial intelligence and data analytics are facilitating predictive maintenance, reducing downtime, and enhancing overall productivity. As the industry navigates these challenges, the focus on integrating cutting-edge technologies continues to drive the next generation of processing machinery, enabling industries to remain competitive and responsive to market changes.

This chart illustrates the key areas of focus within modern processing machinery technology. The data highlights the challenges such as automation and efficiency, while also showcasing the innovations aimed at cost reduction, sustainability, and overall technological advancement.