- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

In today’s industrial landscape, the efficiency of moisture removal plays a crucial role in enhancing product quality and safety. Drying systems have become an essential component across various sectors, including food processing, pharmaceuticals, and materials manufacturing. According to a recent report by the International Drying Association, improper moisture management can lead to significant losses, with businesses potentially losing up to 10% of their production value due to inadequate drying methods. As industries evolve and consumer demands escalate, optimizing these systems becomes not just beneficial, but imperative.

Dr. Emily Watkins, a leading expert in drying technology, states, “The evolution of drying systems has the potential to redefine efficiency in moisture removal, allowing industries to meet sustainability goals while maximizing output.” Innovations such as infrared drying, microwave drying, and vacuum drying have transformed traditional methods, offering stakeholders a range of options to address specific moisture-related challenges. This article explores the top 10 drying systems that demonstrate exceptional performance in moisture removal, aiming to provide insights into effective techniques that enhance operational efficiency and product integrity. In our journey through the landscape of drying systems, we will highlight the important factors to consider and the advancements shaping the future of moisture management.

When selecting drying systems, there are several critical considerations to keep in mind to ensure efficient and effective moisture removal. First, it’s essential to evaluate the specific moisture content of the material you intend to dry. Different materials require different drying techniques; for instance, high moisture content might necessitate a more aggressive drying system. Understanding the characteristics of your material helps in choosing the right system that will provide optimal results.

Another important factor is the energy efficiency of the drying system. Systems that consume less energy while delivering high drying performance not only save costs but also align with sustainability goals. Look for systems with advanced technology that can adjust energy usage based on the moisture levels detected.

Tip: Regular maintenance is key to ensuring your drying system operates at peak efficiency. Schedule routine checks and cleanings to prevent any buildup that could impair performance.

Finally, consider the throughput capacity of the drying system. Depending on your production needs, you may require a system that can handle larger volumes within a shorter period. It’s crucial to align the drying capacity with your operational demands to avoid bottlenecks in the production process.

Tip: Always have a contingency plan in place if your drying system fails. Investing in backup systems can prevent delays and ensure continuous operations.

Drying systems are essential in various industries for effective moisture removal, ensuring product quality and extending shelf life. There are several common types of drying systems, each tailored to specific applications and materials. One of the most widely used is the convection drying system, which employs hot air to transfer heat. This method is suitable for an array of materials, from food products to textiles, and is favored for its simplicity and efficiency.

Another popular type is the vacuum drying system, which utilizes reduced pressure to lower the boiling point of moisture, allowing for gentle drying at lower temperatures. This is particularly advantageous for heat-sensitive materials or when preserving volatile compounds is crucial. Additionally, microwave drying systems have gained popularity for their rapid and uniform drying capabilities. By employing microwave energy, these systems can effectively penetrate the material, ensuring even moisture removal throughout the product. Each of these drying systems offers unique benefits, making them suitable for various industrial needs.

| System Type | Application | Efficiency (%) | Typical Moisture Removal Rate (kg/h) | Energy Consumption (kWh/kg) |

|---|---|---|---|---|

| Convection Drying | Food Products | 85% | 50-200 | 2.5 |

| Vacuum Drying | Pharmaceuticals | 90% | 20-100 | 4.0 |

| Freeze Drying | Biological Samples | 92% | 5-30 | 6.0 |

| Microwave Drying | Agricultural Products | 80% | 30-150 | 3.0 |

| Hot Air Drying | Textiles | 75% | 100-300 | 2.0 |

| Spray Drying | Liquid Foods | 88% | 50-200 | 3.5 |

| Infrared Drying | Ceramics | 83% | 10-50 | 2.8 |

| Solar Drying | Fruit & Vegetables | 78% | 5-25 | 1.0 |

| Heat Pump Drying | Wood Products | 87% | 10-60 | 2.2 |

| Rotary Dryer | Minerals | 80% | 100-500 | 3.0 |

The efficiency metrics in moisture removal techniques play a crucial role in optimizing drying systems for various industries, including food processing, pharmaceuticals, and textiles. Recent studies indicate that systems employing heat pump technology can achieve energy efficiency ratios (EER) of up to 4.0, significantly outperforming traditional drying methods. This efficiency not only reduces operational costs but also minimizes carbon footprints, aligning with sustainable practices. According to a report by the International Energy Agency, integrating advanced drying technologies can lead to energy savings of 20-50%, depending on the application and moisture content.

Furthermore, the effectiveness of moisture removal is often quantified through metrics such as drying rate and energy consumption per unit of moisture evaporated. For instance, data suggests that continuous flow drying systems can provide higher drying rates, often exceeding 2.5 kg/h per m² of surface area, especially in applications involving granular materials. Additionally, the choice of drying medium and the control of environmental conditions—such as temperature and humidity—are critical in enhancing moisture removal efficiency. Advanced monitoring and control strategies are now being implemented to fine-tune these parameters, ensuring optimal performance across varying operational scenarios. This alignment of efficiency and effectiveness not only improves product quality but also enhances overall productivity across industries.

In the quest for efficient moisture removal, modern drying systems have integrated innovative technologies that enhance both performance and energy efficiency. One such advancement is the use of microwave drying, which leverages electromagnetic waves to penetrate materials deeply, providing rapid moisture removal while preserving the integrity of the product. This method not only reduces drying time significantly but also minimizes energy consumption, making it an excellent choice for industries where time and resources are critical.

Another noteworthy development is the incorporation of heat pump technology in drying systems. By using low-grade heat from the environment and converting it to a useful form of energy, these systems achieve lower operating temperatures, thus maintaining product quality and reducing the risk of thermal degradation. Furthermore, intelligent control systems equipped with sensors allow for real-time monitoring and adjustment of drying parameters, optimizing the process for various materials while ensuring uniform moisture content throughout. These innovations are paving the way for a new standard in drying systems, focusing on sustainability and efficiency.

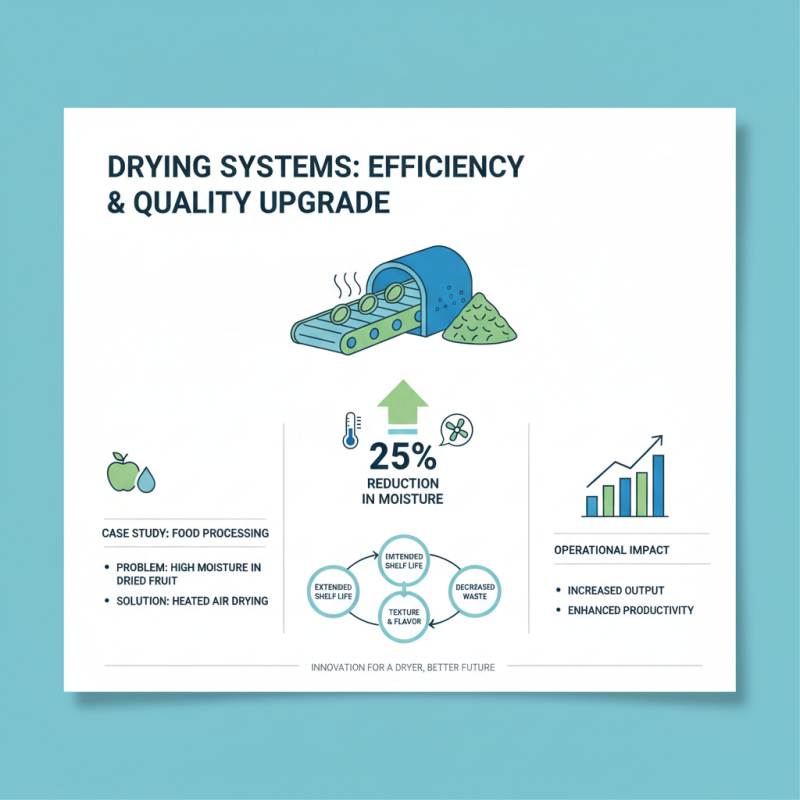

In various industries, the implementation of effective drying systems has significantly improved operational efficiency and product quality. One compelling case study involves a food processing facility that faced challenges with moisture content in dried fruit products. By adopting a heated air drying system, the facility achieved a reduction in moisture levels by over 25%. This enhancement not only extended the shelf life of the products but also improved their texture and flavor. Employees noted a significant decrease in waste and an increase in output, highlighting the drying system's impact on overall productivity.

Another noteworthy example can be found in the textiles industry, where a company struggled with drying time for their cotton fabrics. They integrated a vacuum-assisted drying system that allowed for lower temperature drying, which not only maintained the fabric's integrity but also accelerated the drying process. As a result, the company reported a 40% reduction in drying time, leading to faster production cycles and improved customer satisfaction. These case studies demonstrate that the right drying solutions can lead to substantial benefits, making a compelling argument for investment in efficient drying technologies across various sectors.