- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

The seafood processing industry is a crucial segment of the global economy, projected to reach a market value of over $500 billion by 2025, according to a report by Allied Market Research. This growth underscores the increasing global demand for high-quality fish products, necessitating advanced fish processing equipment to ensure efficiency and maintain product integrity. As operations scale and consumer expectations rise, modern processing facilities are compelled to invest in state-of-the-art tools that enhance productivity while adhering to stringent food safety standards.

In this context, fish processing equipment plays a pivotal role in streamlining operations, from the initial catch to the final packaging. Advanced machinery not only improves the speed and quality of fish processing but also significantly reduces labor costs and waste. For instance, automated systems can increase processing capacity by up to 30%, allowing businesses to meet the rising market demand while ensuring the freshness and quality of their products. Furthermore, the integration of smart technologies enables real-time monitoring and optimization, contributing to sustainable practices within the industry. As we delve deeper into the essential tools for efficient fish processing, it becomes clear that investing in high-quality equipment is no longer optional, but a necessity for success in today's competitive landscape.

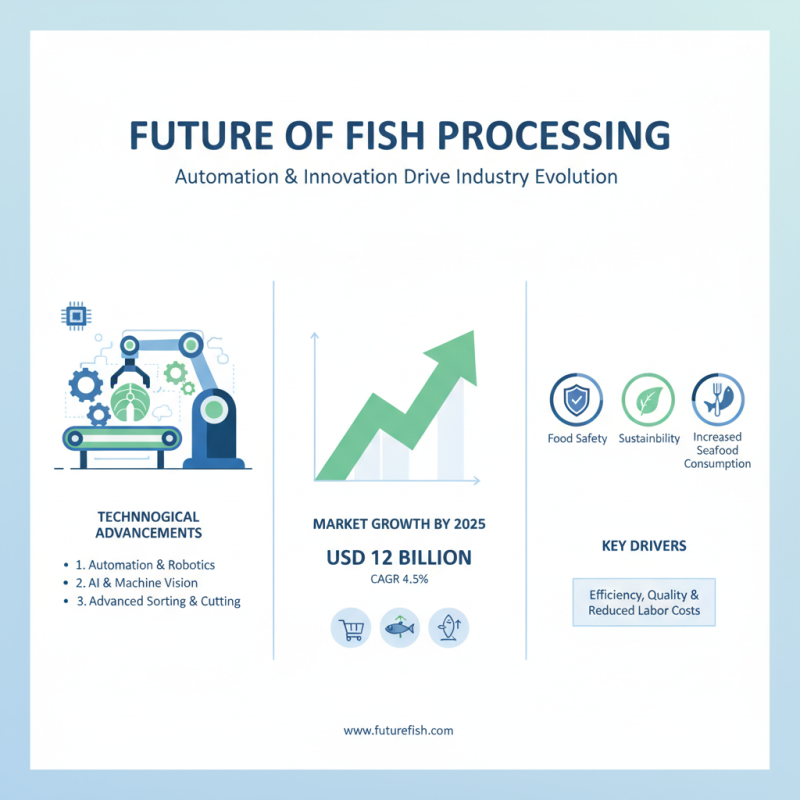

The fish processing industry is experiencing a notable transformation driven by advancements in technology and evolving market demands. As highlighted in recent reports, the global fish processing equipment market is expected to reach USD 12 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.5%. This growth is largely fueled by the rising focus on food safety, sustainability, and the increasing consumption of seafood. Modern processing methods emphasize efficiency and quality through automation, which not only reduces labor costs but also enhances product consistency.

One significant trend in fish processing is the integration of smart technologies. The implementation of IoT (Internet of Things) devices and data analytics enables real-time monitoring and optimization of processing operations, ensuring that quality standards are consistently met while minimizing waste. An industry report by ResearchAndMarkets indicates that nearly 60% of fish processors are in the process of adopting smart technologies to improve operational efficiency. Additionally, the push for environmentally friendly practices has led to innovations in equipment that prioritize energy efficiency and use of sustainable materials, responding to consumers’ increasing preference for eco-conscious products. This combination of technology and sustainability is steering the future of fish processing towards greater efficiency and quality in output.

Fish processing equipment plays a crucial role in enhancing efficiency and ensuring quality in the seafood industry. Among the key types of equipment, fish filleting machines are essential for streamlining the initial processing stage. These machines can significantly reduce labor costs and processing time, achieving filleting with precision. According to a report by MarketsandMarkets, the global fish processing equipment market is expected to reach USD 2.4 billion by 2025, highlighting the growing reliance on automation and advanced machinery in fish processing.

Another important category of fish processing equipment includes freezing and chilling systems. These systems are vital for preserving the freshness and nutritional value of seafood products. Freezing equipment, such as plate freezers and blast freezers, can quickly reduce the temperature of fish, thus inhibiting the growth of harmful bacteria. The Food and Agriculture Organization (FAO) indicates that proper freezing methods can extend the shelf life of fish products by up to 12 months without significant loss of quality. Additionally, these systems contribute to waste reduction, a critical factor as reports suggest that nearly 30% of fish harvested globally ends up wasted due to inadequate handling and storage.

Quality control systems, including metal detectors and checkweighers, are also essential in fish processing. These tools ensure that the final product meets safety standards and is free from contaminants. The implementation of advanced quality assurance measures is increasingly important, as consumers demand higher safety standards. A recent study by Technavio revealed that investments in quality control technologies can lead to an increase in product acceptance rates, thereby boosting overall profitability for processing plants.

The adoption of automated fish processing systems has proven to significantly enhance efficiency in the seafood industry. According to a report by MarketsandMarkets, the global fish processing equipment market is projected to reach $17.9 billion by 2025, driven largely by the increasing demand for efficient processing solutions. Automation not only accelerates processing times but also improves accuracy and consistency in product quality. For instance, automated filleting machines can increase throughput by over 30% compared to manual processing, allowing facilities to meet rising consumer demands while minimizing labor costs.

Moreover, the integration of advanced technologies such as robotics and AI into fish processing operations contributes to reduced waste and improved yield. A study from the Food and Agriculture Organization (FAO) indicates that inefficient processing methods can lead to a loss of up to 20% of total fish biomass. By implementing automated systems, companies can optimize their operations, thereby reclaiming a significant portion of this waste and increasing profitability. The strategic incorporation of these technologies not only enhances productivity but also positions businesses to better compete in the increasingly rigorous and quality-focused seafood market.

| Equipment Type | Key Features | Efficiency Gain (%) | Quality Improvement (%) | Maintenance Frequency (Months) |

|---|---|---|---|---|

| Filleting Machine | Automated precision cutting | 30 | 25 | 6 |

| Fish Grading System | Weight and size sorting | 20 | 15 | 12 |

| Smokehouse | Automated temperature control | 18 | 20 | 8 |

| Portioning Machine | Custom size portions | 25 | 30 | 10 |

| Vacuum Packing Machine | Extended shelf life packaging | 22 | 15 | 6 |

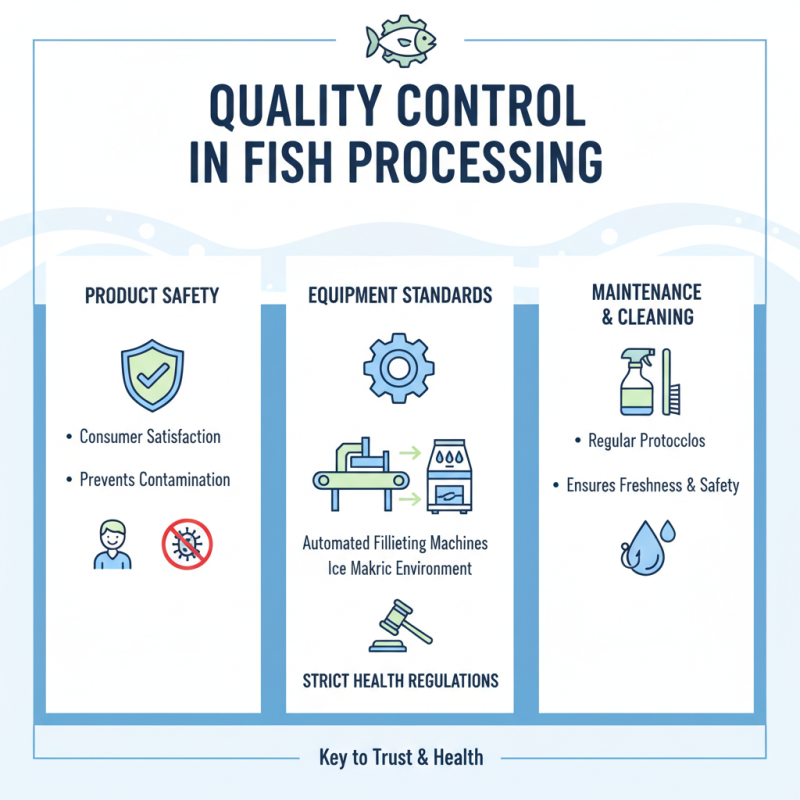

Quality control is paramount in fish processing, as it directly affects product safety and consumer satisfaction. Implementing rigorous equipment standards ensures that the processing environment is hygienic and that fish are handled safely. Essential tools like automated filleting machines and ice makers are critical in maintaining freshness. These machines must comply with strict health regulations to prevent contamination, emphasizing the need for regular maintenance and cleaning protocols.

In addition to equipment standards, adopting best practices in quality control is vital for successful fish processing operations. This includes training staff in proper handling techniques, using calibrated instruments for measuring temperatures, and routinely checking the conditions of storage areas. The adoption of sensors and monitoring systems can enhance oversight of processing stages, enabling real-time adjustments that uphold product quality. Investing in advanced processing technology not only improves efficiency but also reinforces a commitment to delivering high-quality fish products to the market.

The technological advancements in fish processing have significantly enhanced both yield and quality, revolutionizing how the industry operates. Modern equipment such as automated filleting machines, precision weighing systems, and advanced freezing technologies have streamlined production processes, reducing manual labor and minimizing processing time. This not only increases efficiency but also helps maintain the freshness of the fish, which is critical for preserving quality. Enhanced tracking and monitoring systems further contribute to optimal processing by ensuring that temperature and sanitation standards are consistently met throughout the production line.

Moreover, innovations like blockchain for traceability and data analytics for operational optimization are transforming decision-making in fish processing. By providing real-time data on various stages of processing, these technologies enable businesses to identify bottlenecks and areas for improvement quickly. Enhanced quality control measures, facilitated by machine learning algorithms, allow processors to detect defects and inconsistencies earlier in the process, ensuring that only the highest quality products reach consumers. As a result, these advancements not only improve the overall efficiency of fish processing operations but also enhance product quality, leading to greater consumer satisfaction and reduced waste.

This chart illustrates the efficiency and quality scores for different fish processing methods. As technology advances, machine-assisted methods greatly improve efficiency while maintaining high quality. Hand filleting scores lower in both metrics compared to machine filleting, which reflects the impact of technological advancements in the fish processing industry.