- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

The food machinery sector is undergoing a transformative evolution in 2023, driven by advancements in technology and an increasing demand for efficiency and sustainability. Recent reports by the Food Processing Machinery Association indicate that the global food machinery market is projected to reach $95 billion by 2025, marking a significant compound annual growth rate (CAGR) of 7.5%. This highlights the industry's pivotal role in supporting the growing food supply chain while addressing the challenges posed by a rapidly changing environment.

According to Dr. Emily Carter, a leading expert in food technology, "Innovations in food machinery not only enhance production efficiency but also play a crucial role in minimizing waste and improving product quality." The trend towards automation and digitalization is reshaping how manufacturers approach food production, ensuring that they can meet the ever-increasing consumer demands for convenience and quality. As sustainability remains at the forefront of industry practices, various trends such as the incorporation of smart technology, machine learning, and eco-friendly materials are becoming essential in the design and operation of food machinery.

In this evolving landscape, understanding the top trends in food machinery will be vital for stakeholders looking to stay competitive and responsive to market demands. Embracing these innovations will not only help companies optimize their operations but also align with global efforts to promote sustainable and responsible food production practices.

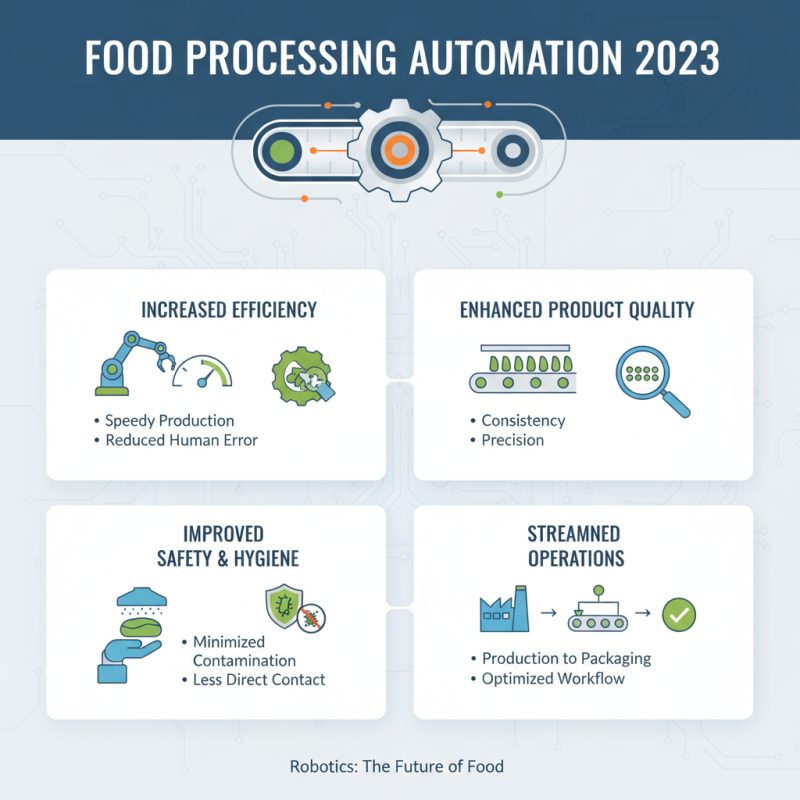

As the food machinery industry evolves, 2023 marks a pivotal year for the adoption of emerging technologies that enhance operational efficiency and product quality. One significant trend is the increasing use of automation and robotics in food processing. According to a recent report from MarketsandMarkets, the global food automation market is projected to reach USD 14.22 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.48% from 2021. These advancements not only streamline production lines but also reduce labor costs and mitigate human error, ensuring higher consistency and safety standards.

Another noteworthy development is the integration of the Internet of Things (IoT) in food machinery. The 2023 Global IoT in Food and Beverage report indicates that the market is expanding rapidly, with an estimated CAGR of 12.07% from 2022 to 2027. By employing IoT solutions, manufacturers gain real-time insights into their machinery’s performance and maintenance needs, resulting in less downtime and enhanced overall productivity. Furthermore, smart sensors can monitor food quality, contributing to improved traceability and compliance with stringent food safety regulations, ultimately benefiting both producers and consumers.

| Trend | Description | Impact on Industry | Potential Challenges |

|---|---|---|---|

| Automation & Robotics | Increased use of automated systems and robotics to enhance production efficiency. | Higher output and lower labor costs. | High initial investment and maintenance costs. |

| IoT Integration | Connecting machinery to the Internet for real-time data collection and monitoring. | Improved decision-making through data analytics. | Cybersecurity risks and data privacy concerns. |

| Sustainability Practices | Adopt environmentally friendly practices and technologies in food production. | Reduction in waste and energy consumption. | Potential for higher operational costs in the short term. |

| Smart Packaging | Development of packaging that provides information on freshness and safety. | Enhanced consumer safety and reduced food waste. | Implementation costs and potential issues with consumer acceptance. |

| Data Analytics | Utilizing big data to improve operational efficiencies and product quality. | Informed strategic decisions that can lead to increased profitability. | Need for skilled personnel and data management systems. |

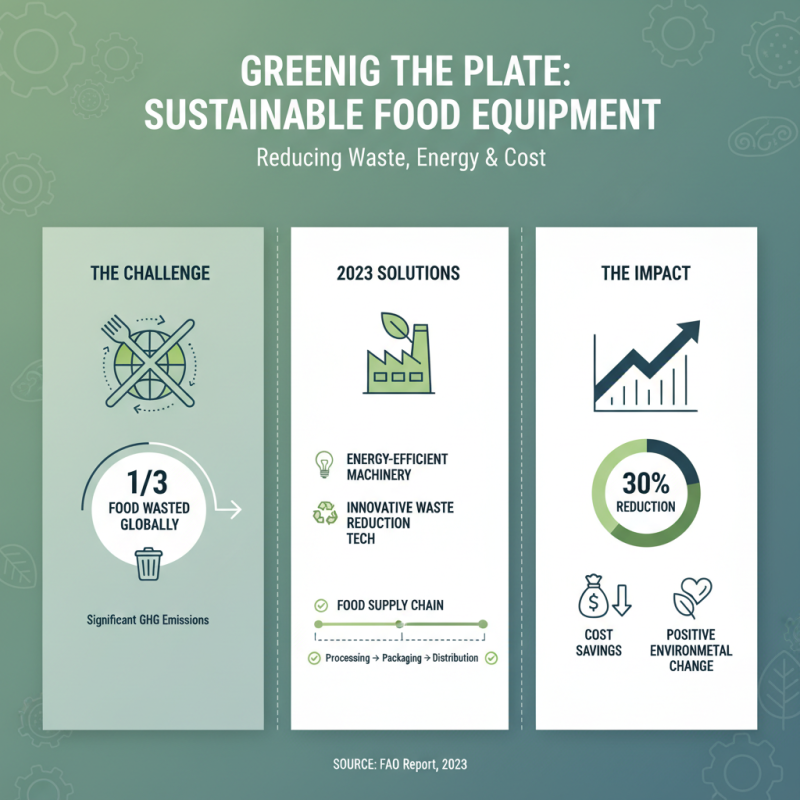

Sustainability has become a critical focal point in the food production equipment industry as companies strive to minimize their environmental impact. According to a recent report by the Food and Agriculture Organization (FAO), around one-third of food produced globally is wasted, contributing significantly to greenhouse gas emissions. In 2023, manufacturers are increasingly adopting energy-efficient machinery and innovative technologies that reduce waste throughout the food supply chain. Research indicates that investing in sustainable food machinery can lead to an energy reduction of up to 30%, showcasing the potential for both cost savings and positive environmental impact.

Moreover, advancements in automation and data analytics are playing a significant role in enhancing sustainability practices. A study by the International Institute of Refrigeration highlights that smart technologies can optimize production processes by minimizing excess energy use and improving resource allocation. For instance, predictive maintenance in equipment can prevent unexpected breakdowns, leading to less downtime and a more efficient use of resources. With regulatory bodies also advocating for sustainable practices, food manufacturers are increasingly recognizing that integrating such technologies not only aligns with environmental goals but also meets the growing consumer demand for sustainable products.

Automation and robotics are fundamentally transforming the landscape of food processing in 2023. As the demand for efficiency and precision increases, many food manufacturers are turning to advanced automation technologies to streamline operations. Automated systems enhance production speed and reduce human error while improving consistency and product quality. This trend is particularly vital in an industry where safety and hygiene are paramount; robotics can minimize direct human contact with food, thereby reducing contamination risks.

Furthermore, the integration of AI and machine learning into robotic systems is revolutionizing how food is processed and packaged. With sophisticated algorithms, machines can analyze data in real-time, adjusting processes to optimize resource utilization and maintain high standards of quality control. Collaborative robots, or cobots, are increasingly being deployed alongside human workers, allowing for a seamless blend of human ingenuity and machine efficiency. This collaboration enhances productivity without compromising the hands-on approach that is often necessary in food preparation. As these technologies evolve, they promise to make food processing not only more efficient but also more adaptable to changing consumer demands and market conditions.

The impact of artificial intelligence (AI) on food machinery efficiency is a pivotal trend for 2023. As the food industry seeks to enhance productivity and reduce waste, AI integration in machinery becomes increasingly essential. According to a recent report by the Food Processing Technology, using AI can lead to a reduction in operational costs by up to 30%, while also improving output quality and speed. AI algorithms help in predictive maintenance, allowing machines to self-diagnose issues before they escalate into costly failures, thereby optimizing uptime and productivity.

Tips for incorporating AI into food machinery include conducting a thorough assessment of current processes to identify areas where AI can deliver the most value. Investing in AI training for staff can also ensure that the workforce adapts smoothly to these technological advancements. Furthermore, utilizing AI for data analytics can empower businesses to make informed decisions based on real-time insights, fostering continuous improvement in operations.

Another significant benefit of AI is its ability to enhance food safety. By utilizing machine learning algorithms to monitor production conditions, companies can detect anomalies and initiate corrective actions swiftly. This not only lowers the risk of contamination but also builds consumer trust in food quality. As companies navigate these technological transformations, embracing AI-driven machinery will likely become a key differentiator in the highly competitive food industry landscape.

The food machinery industry in 2023 faces several critical challenges that could shape its future. One significant issue is the increasing demand for automation and smart technology integration. According to a report by the Food Processing Machinery Association, approximately 60% of food manufacturers are prioritizing automation to enhance efficiency and reduce operational costs. However, integrating these advanced technologies poses challenges such as the need for skilled labor to operate complex machinery and the high initial investment costs associated with upgrading equipment.

Another pressing challenge is sustainability in food processing. The global emphasis on reducing carbon footprints has led many companies to re-evaluate their production processes. A survey conducted by the Global Food Machinery Council revealed that nearly 75% of industry leaders are actively seeking sustainable solutions, with specific focus on energy-efficient machinery and waste reduction practices. Despite the push for greener technologies, the transition often involves significant R&D expenditures and longer timelines for implementation, which can strain resources for smaller manufacturers.

Lastly, supply chain disruptions continue to affect the food machinery sector. The impact of the COVID-19 pandemic highlighted vulnerabilities in global logistics, with many companies experiencing delays in receiving critical components. The Food Industry Report projects that 40% of machinery manufacturers will face ongoing supply chain challenges in the coming year, complicating their ability to meet growing market demands. Addressing these issues will be essential for the sector to maintain growth and competitiveness in 2023 and beyond.