- Food processing equipment

Applications

Products

- Washing & drying systems

- Service

Menu

In the ever-evolving landscape of processing machinery, innovation plays a crucial role. Experts emphasize the need for advancements to enhance productivity. John Smith, a leading figure in the machinery sector, once noted, "Efficiency in processing machinery is the key to future growth." His insight reflects the urgency for ongoing improvements.

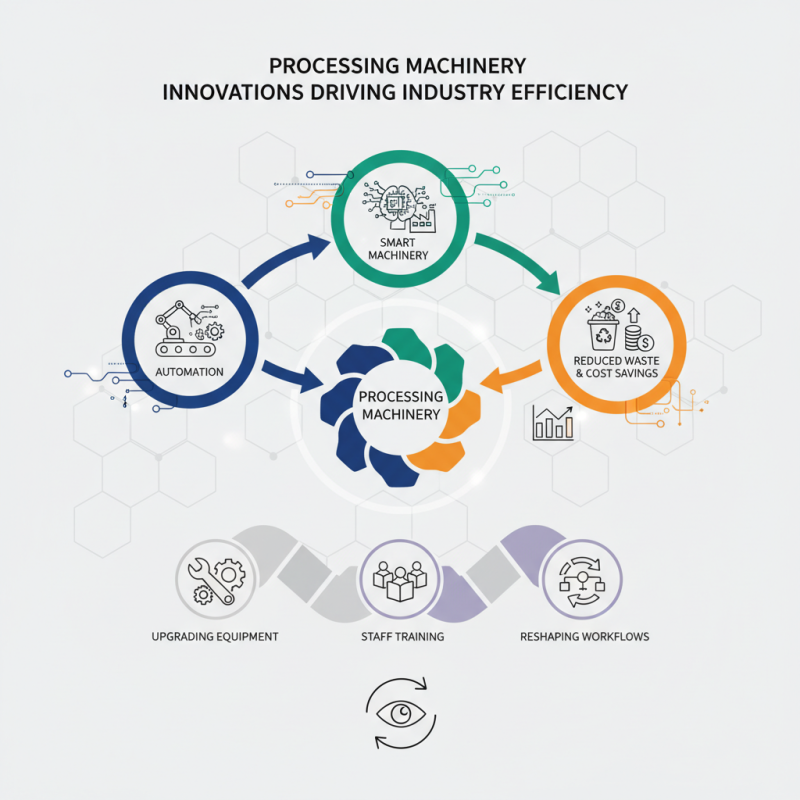

Today’s manufacturing industry faces intense competition. Companies strive to integrate new technologies, from automation to smart machinery. These innovations can streamline operations, reduce waste, and significantly cut costs. However, not all advancements are easy to adopt. While businesses recognize the benefits, some struggle with implementation.

The challenge lies in balancing innovation with practicality. It’s essential to evaluate which technologies align with specific operational needs. As the sector evolves, processing machinery must adapt. This adaptation is not just about upgrading equipment; it includes training staff and reshaping workflows. Continuous reflection on these processes is vital for sustained success.

The processing machinery industry is witnessing a wave of innovations that significantly boost efficiency. Emerging technologies, such as IoT and AI, are revolutionizing operations. A recent report indicated that companies adopting these technologies improve efficiency by up to 30%. This transformation is helping manufacturers to optimize production lines and reduce downtime.

Automation tools, including advanced robotics, are enhancing precision in processing tasks. This precision reduces waste, leading to more sustainable practices. For instance, predictive maintenance systems can minimize machine failures. They utilize real-time data to anticipate issues before they disrupt production. The trend shows that leveraging such innovative systems can save companies up to 20% in maintenance costs.

**Tip:** Embrace smart automation. It's a crucial step toward maximizing efficiency. Small adjustments can lead to significant gains. Continuously assess your existing processes. Reflect on what's working and what isn't. Adapt strategies based on insights gathered from data analytics. This iterative approach fosters a culture of continuous improvement.

The rise of IoT technology is transforming machinery performance monitoring in significant ways. Sensors placed in machinery provide real-time data. This data allows for better predictive maintenance and improved efficiency. By tracking performance metrics, operators can spot issues before they escalate. However, this technology is not without its challenges.

One concern remains data interpretation. Machines generate vast amounts of data daily. Distinguishing useful insights from noise can be overwhelming. Operators need training and experience to navigate complex data sets effectively. Additionally, the reliance on data may lead to complacency, where operators trust the system too much. Balancing human insight with automated alerts is crucial.

Another point to ponder is the initial cost of implementing IoT systems. While they promise long-term savings, the upfront investment can be daunting. Many businesses hesitate to take that leap. They wonder if the benefits truly justify the expense. Despite these hurdles, the potential for enhanced efficiency makes this technology hard to ignore. Adaptation may take time, but the rewards can be substantial.

The manufacturing sector is experiencing a significant shift due to robotics. Automation is enhancing production speed and precision. According to recent industry reports, companies adopting robotics have increased their output by 30%. This trend is not merely about replacing human labor; it is about augmenting capabilities. The integration of robots into manufacturing processes often leads to a 20% reduction in operational costs over time.

Tips: Evaluate your current workflows to identify repetitive tasks. These tasks are prime candidates for robotic assistance.

Despite the advantages, there are challenges. The initial investment for robotic systems can be daunting. Companies may struggle with the integration process. Training staff to work alongside robots requires time and resources. Reports indicate that 40% of businesses face obstacles during implementation. The fear of job losses can also hinder progress, creating resistance among employees.

Tips: Involve teams in the planning stages. This can help ease concerns and foster a collaborative environment.

The landscape is evolving quickly, and companies must adapt or risk falling behind. Automation is reshaping industry standards, but the transition is complex. Embracing this change requires careful planning and consideration of both workforce and technology. Companies that manage this integration well often find themselves leading the pack in efficiency and innovation.

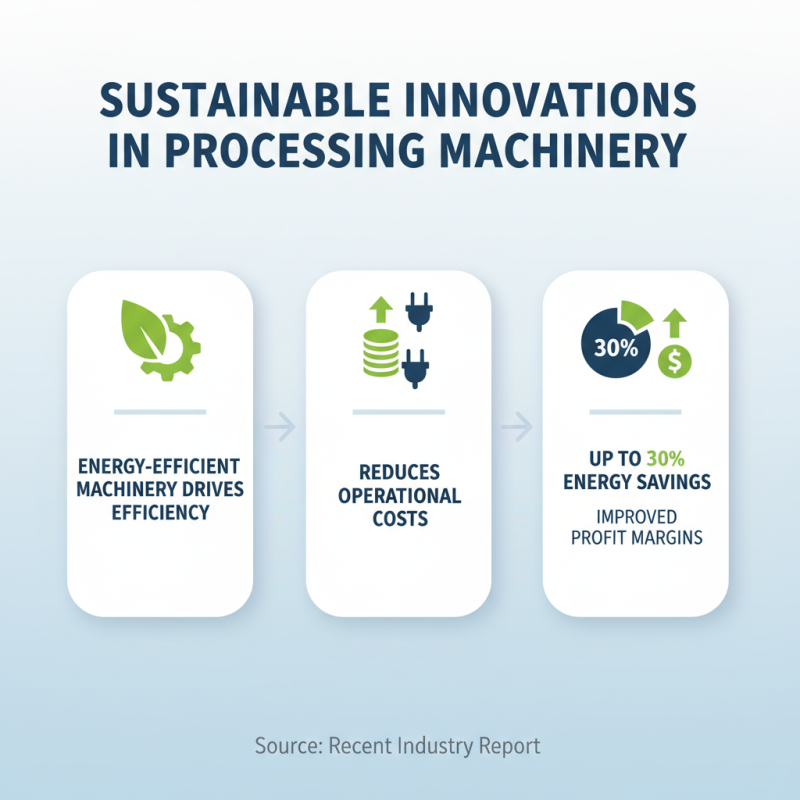

In today's fast-paced environment, sustainable innovations in processing machinery play a crucial role in driving industry efficiency. Energy-efficient machinery can significantly reduce operational costs. According to a recent industry report, companies that invest in energy-efficient technology save up to 30% on energy bills. This is a substantial reduction, contributing directly to improved profit margins.

Moreover, the transition to advanced machinery often leads to lower maintenance costs. For example, newer models are designed with longer-lasting components. This means fewer breakdowns and less downtime. However, not all companies embrace these changes. Some remain hesitant due to initial investment costs. This mindset can hinder progress and sustainability.

The impact of energy-efficient machinery is becoming more evident. A study found that businesses adopting green technologies reported a 25% increase in productivity over three years. Yet, there are challenges. Older equipment can be less compatible with new technologies, creating integration issues. Businesses must adapt and rethink their strategies to fully capitalize on these innovations. Balancing costs and long-term benefits is critical for success in today's competitive market.

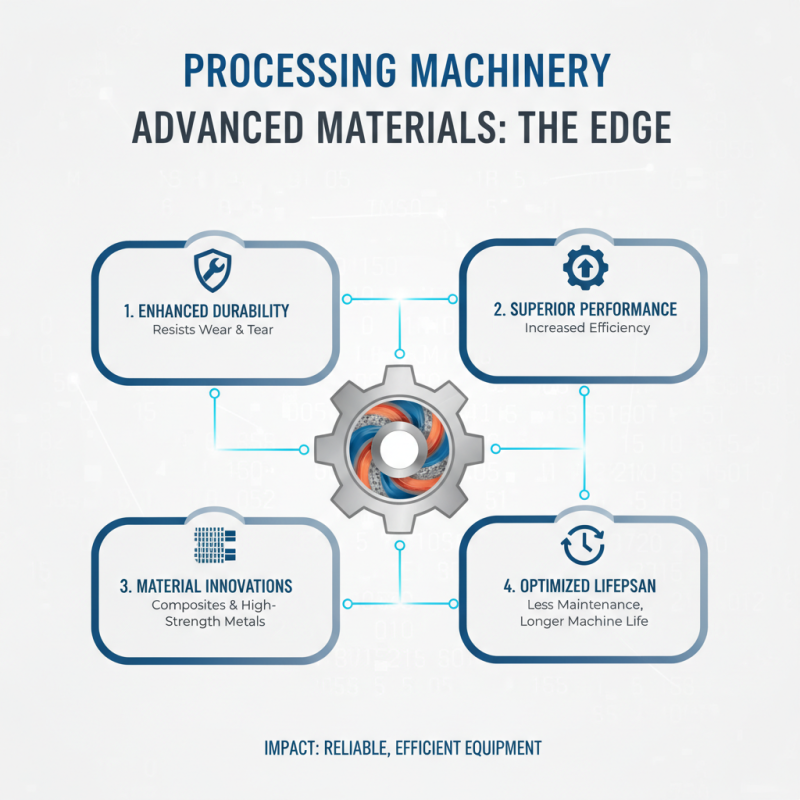

In the processing machinery sector, advanced materials play a crucial role. These materials enhance durability and performance, impacting efficiency. Utilizing composites and high-strength metals, manufacturers can create equipment that withstands extreme conditions. This results in longer-lasting machines that require less maintenance.

The introduction of lightweight, yet robust, materials is transforming equipment designs. This shift allows for more efficient energy consumption. Processors are noticing reduced wear and tear on components. However, sourcing these advanced materials can be challenging. Sometimes, the initial costs may deter manufacturers from adopting new technologies. It's essential to weigh the long-term benefits against upfront investments.

Moreover, while these innovations promote performance, they can also lead to design complexities. Engineers must adapt to new properties and behaviors of advanced materials. Each design iteration carries a risk of unforeseen issues. Continuous testing and feedback will ultimately ensure these materials meet industry demands. Balancing innovation with practicality presents a learning curve for many.